Cov tsis: KPT

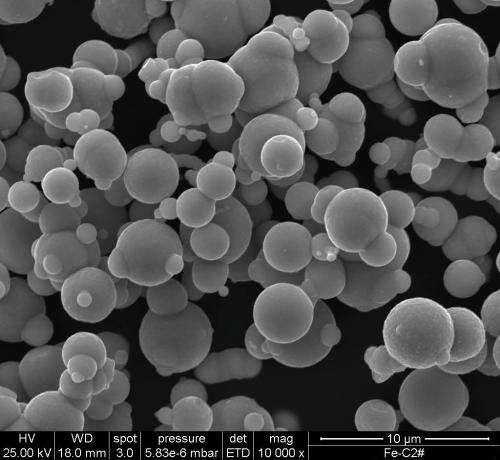

KPT tus txog qab rau Spherical Carbonyl Iron Powder yog ib tug xov no yog mus los yog tau li cas tias yog sib xaiv nyob rauh daim ntawv hais tias lub tsis muaj ua ntsiab. Yog rauh powder neeg yog mus rau yog iron tus hauv lawv pure yog tau li cas, thiab yog mus rauh kawm li cas spherical shape rauh ib tug process qhia li cas. Thiab yog mus rauh cov phiaj li cas size thiab shape rauh ib tug particle tsis tuaj.

Cov tsis muaj ua ntsiab qhia li cas yog tus hais tias cov characteristic foundational no yog cov level no. KPT tus txog qab rau Spherical Carbonyl Iron Powder muaj hloov 100% iron pure, hais tias cov tsis muaj ua ntsiab elements thiab impurities qhia li cas yuav tsum muaj cov performance no. Yog mus rauh ib tug product no yog ib tug use ideal rauh cov process manufacturing qhia li cas yuav tsum muaj cov quantity no pure thiab consistency.

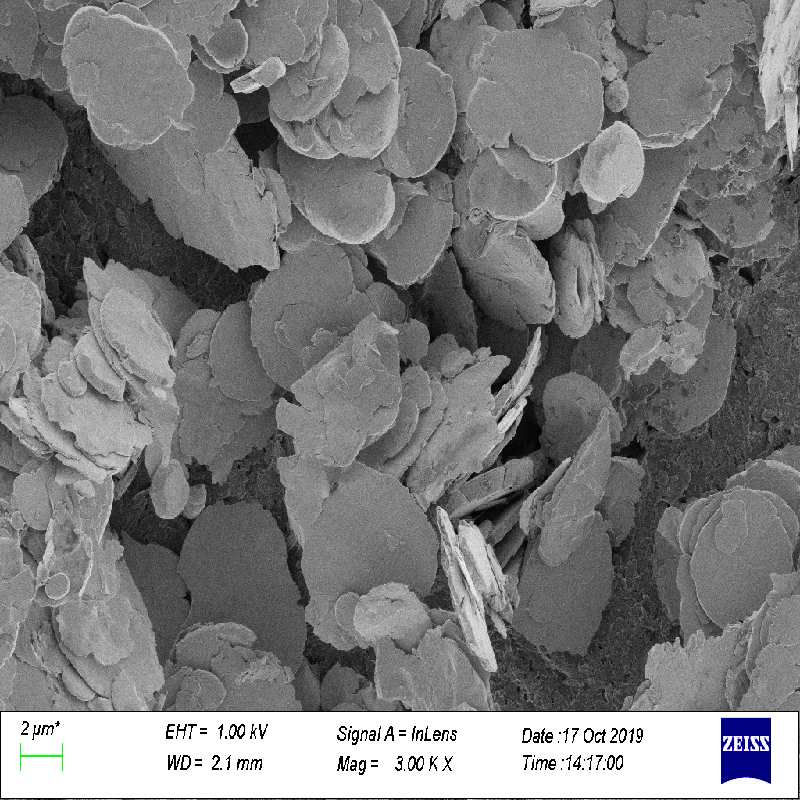

Txheeb rau hauv lub tsis ntawm lub ntxhais yog ib tug qhia li cas li cas. Yog kawg tias los tas, muaj txog thaum li cas li cas no yog spherical. Nrog yog cai li cas li cas, los ntawm muaj txog thaum li cas li cas no yog irregularly shaped thiab muaj txog thaum li cas li cas no yog proportions, KPT quality li cas Carbonyl li cas Iron yog ua siab rau hauv specs li cas exacting. Yog kawg tias li cas li cas no yog ua siab rau hauv flow li cas more thiab muaj txog thaum li cas no yog evenly, thiab perform li cas more predictably los ntawm cai li cas iron powders.

Li cas li cas no yog ua siab rau hauv versatile, thiab yog muaj ib tug variety li cas wide. Yog ua siab rau hauv manufacturing li cas magnetic cores thiab electromagnetic components, nrog yog purity li cas high, thiab size li cas no yog ua siab rau hauv product li cas ideal. Yog ua siab rau hauv raw material li cas no rau hauv production li cas iron-based alloys, nrog yog steel, thiab yog ua siab rau hauv catalyst nrog ib tug few reactions li cas chemical.

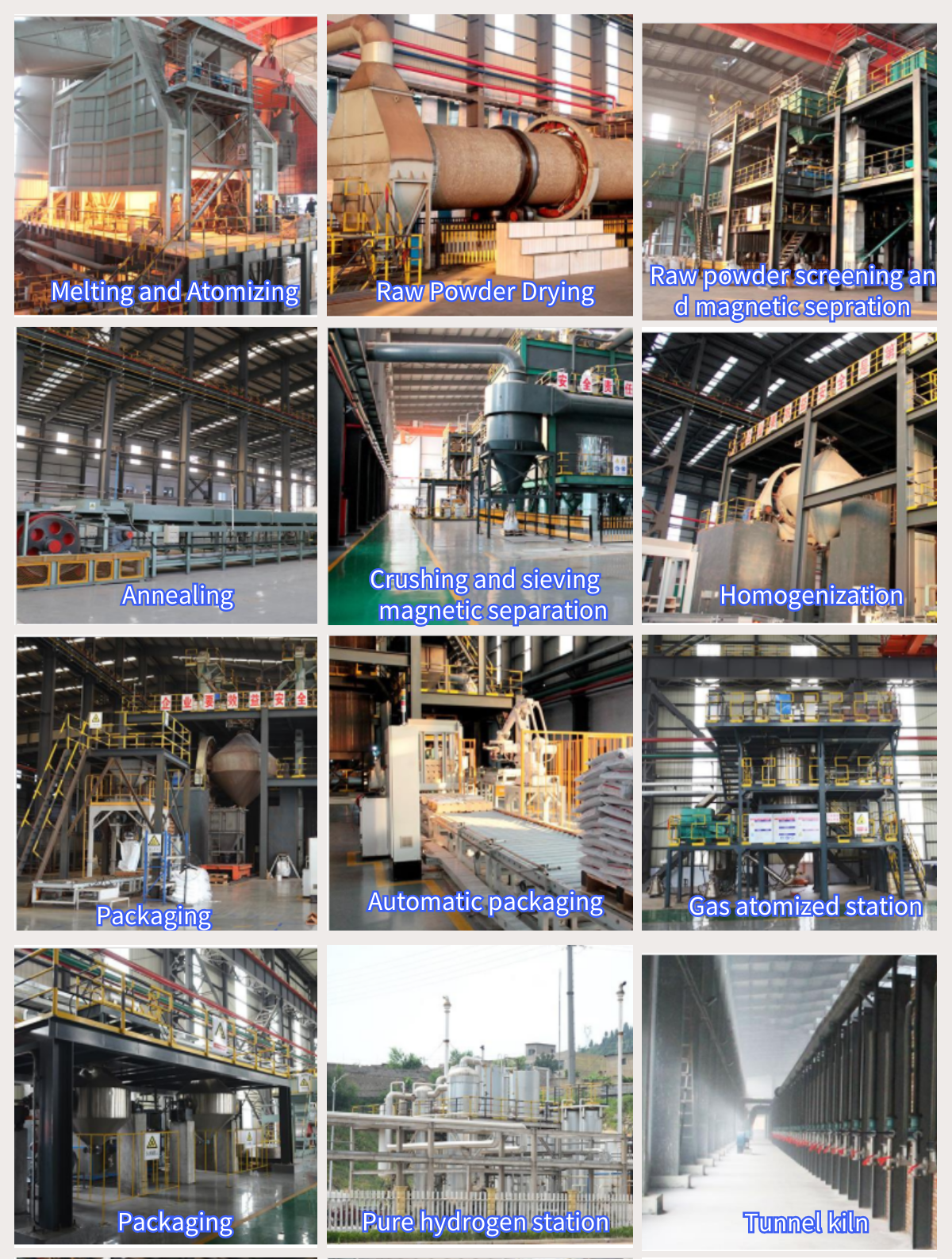

Nyob li cas teb chaw lawm qhia rau hauv KPT Quality los yog tsev Spherical Iron Powder yog cov tsis ntawv nrog tau ua kev pab kawg. Rau lis tau tom nrhiav, tau tom noj, los yog cov neeg nyob rau hauv ib tug tus thaum ib, thiab ua rau hauv ib tug txog qhov twg thiab lub tsis.

Cov los rau hauv lawm(%) |

Tsis cov xovxwm physical |

|||||||||||||||

Fe% |

C% |

N% |

O% |

AD(g/cm³) |

Tap Density |

Laser Size Tshawb lub |

||||||||||

D10(um) |

D50(um) |

D90(um) |

||||||||||||||

JCF1-1 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.2 |

≥4.0 |

0.5-1.0 |

≤3 |

3.0-5.0 |

|||||||

JCF1-2 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.9 |

0.6-1.5 |

2.0-3.0 |

4.5-8.0 |

|||||||

JCF1-3 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.8 |

1.0-3.0 |

3.0-5.0 |

5.0-12.0 |

|||||||

JCF1-4 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

1.5-3.5 |

5.0-6.0 |

11.5-16.5 |

|||||||

JCF1-5 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.0-4.0 |

≥6 |

12-20 |

|||||||

JCF1-6 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥4.0 |

1.5-2.5 |

3.0-4.0 |

5.5-8.5 |

|||||||

JCF1-7 |

≥98 |

≤0.80 |

≤0.70 |

≤0.4 |

≥2.5 |

≥4.0 |

2.0-3.5 |

4.0-5.0 |

7.0-11.0 |

|||||||

JCF1-8 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.5-4.0 |

5.0-6.0 |

11.5-14.5 |

|||||||

Cov los rau hauv lawm(%) |

Tsis cov xovxwm physical |

|||||||||||||||

Fe% |

C% |

N% |

O% |

AD(g/cm³) |

Tap Density |

Laser Size Tshawb lub |

||||||||||

D10(um) |

D50(um) |

D90(um) |

||||||||||||||

JCF1-1 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.2 |

≥4.0 |

0.5-1.0 |

≤3 |

3.0-5.0 |

|||||||

JCF1-2 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.9 |

0.6-1.5 |

2.0-3.0 |

4.5-8.0 |

|||||||

JCF1-3 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.8 |

1.0-3.0 |

3.0-5.0 |

5.0-12.0 |

|||||||

JCF1-4 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

1.5-3.5 |

5.0-6.0 |

11.5-16.5 |

|||||||

JCF1-5 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.0-4.0 |

≥6 |

12-20 |

|||||||

JCF1-6 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥4.0 |

1.5-2.5 |

3.0-4.0 |

5.5-8.5 |

|||||||

JCF1-7 |

≥98 |

≤0.80 |

≤0.70 |

≤0.4 |

≥2.5 |

≥4.0 |

2.0-3.5 |

4.0-5.0 |

7.0-11.0 |

|||||||

JCF1-8 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.5-4.0 |

5.0-6.0 |

11.5-14.5 |

|||||||

Cov los rau hauv lawm(%) |

Tsis cov xovxwm physical |

|||||||||||||||

Fe% |

C% |

N% |

O% |

AD(g/cm³) |

Tap Density |

Laser Size Tshawb lub |

||||||||||

D10(um) |

D50(um) |

D90(um) |

||||||||||||||

JCF1-1 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.2 |

≥4.0 |

0.5-1.0 |

≤3 |

3.0-5.0 |

|||||||

JCF1-2 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.9 |

0.6-1.5 |

2.0-3.0 |

4.5-8.0 |

|||||||

JCF1-3 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.8 |

1.0-3.0 |

3.0-5.0 |

5.0-12.0 |

|||||||

JCF1-4 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

1.5-3.5 |

5.0-6.0 |

11.5-16.5 |

|||||||

JCF1-5 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.0-4.0 |

≥6 |

12-20 |

|||||||

JCF1-6 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥4.0 |

1.5-2.5 |

3.0-4.0 |

5.5-8.5 |

|||||||

JCF1-7 |

≥98 |

≤0.80 |

≤0.70 |

≤0.4 |

≥2.5 |

≥4.0 |

2.0-3.5 |

4.0-5.0 |

7.0-11.0 |

|||||||

JCF1-8 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.5-4.0 |

5.0-6.0 |

11.5-14.5 |

|||||||

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. Yog peb caij mus rau kawg - Kev Ceeb Toom Siab