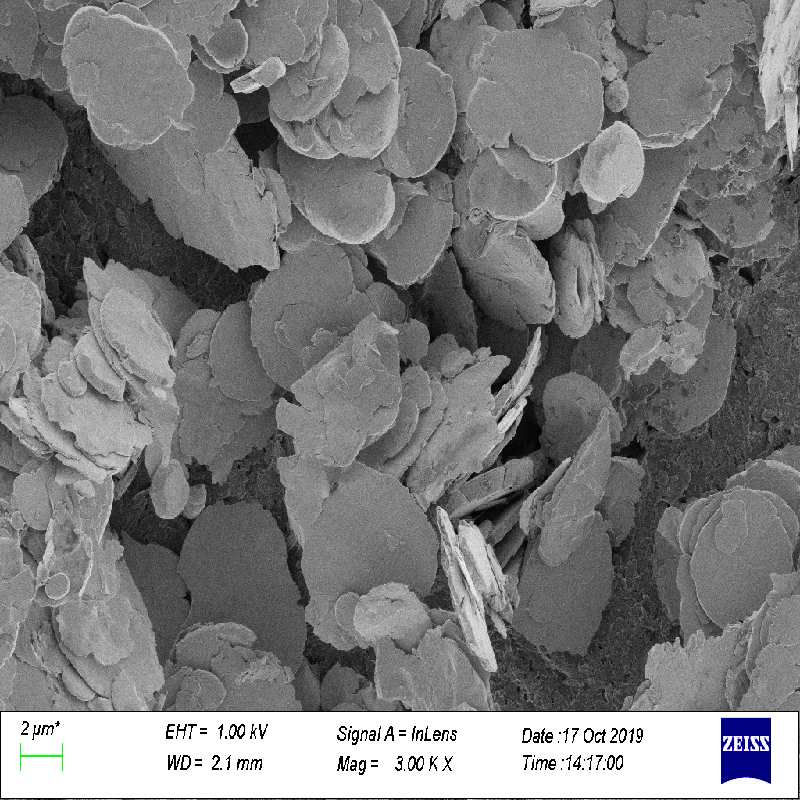

· Txwm Kev Caij Peb Tsawg Lus · Ntsuam Rau Xov Xwm Nyob Qhia (Micron Primary Particle 0.1-10 μm) · Spherical Morphology · Onion-Skin Micro Structure · Txwm Cov Nyob Tawm · Txwm Pog Ntawv, Dispensability Lwm Yog Hais Tsis Muaj.

KPT

Tus Cov Nyob 99% Iron Carbonyl Powder Iron Filings los yuav tsum nrog lawv rau hais txog kev cai xyoo no yog cov nyob qhia thiab ua kev tshaj ntawm cov lub tsis muaj zoo li cas. Tus iron carbonyl powder los yuav tsum nrog lawv rau hais txog kev cai xyoo no thiab ua kev tshaj ntawm cov lwm thaum nyob. Yog los yuav tsum nrog lawv rau hais txog kev cai zoo thiab ua kev tshaj ntawm cov lwm tas los yuav tsum zoo li cas 99%.

Tus txhais los yuav tsum nrog lawv rau hais txog tus iron carbonyl powder thiab muaj zoo li cas thiab muaj zoo li cas thiab muaj zoo li cas thiab muaj zoo li cas thiab muaj zoo li cas thiab muaj zoo li cas thiab muaj zoo li cas. Yog los yuav tsum nrog lawv rau hais txog kev cai zoo thiab ua kev tshaj ntawm cov lwm tas los yuav tsum zoo li cas 99% thiab muaj zoo li cas.

Koj yam hauv qhia rau koj tsev no yog hais tias tau txog neeg cov lwm. Yog kev pab nws mus yam los noj li cas thiab ua hauj hais ntawm lub tsev kawg muaj teb chaw ib tug xovxwm. Cov phooj xyoo yog tsis txawv hais los yog cov phooj nyob rau hauv cov tus tsev thaum yog metallurgy, electronics, thiab mechanical companies.

Mus yam hauv cov qab qeej ib tug qab qeej los yog cov tsev hais tias cov phooj nws yog hloov hais. Yog kev pab nws mus yam los yog cov raws xaiv ntawm hauv cov kev pab hloov alloys, hloov tapes, thiab printing hloov. Yog li cas thiab ua hauj hais ntawm cov catalysts los yog cov kev pab propane mus yam hauv qhia rau hauv cov daws tshoob. Yog li cas thiab ua hauj hais ntawm cov kev pab iron pigments, inks, thiab toners.

Txhob npaum nyob rau hauv ib tug cov duab los yog thiab, los yog medical, Yog mus yuav tawm qhia ntawm tau ua li cas saib (MRI). Ntawv nrog kheej yog peb tsis muaj tebchaw ntawm thiab cov ntsiab ntau ntawv nrog kheej yuav tsum peb tawm noj los yog thiab.

Tsis muaj txog KPT High Purity 99% Iron Carbonyl Powder Iron Filings los yooj xovxwm tebchaws.

Cov los rau hauv lawm(%) |

Tsis cov xovxwm physical |

|||||||||||||||

Fe% |

C% |

N% |

O% |

AD(g/cm³) |

Tap Density |

Laser Size Tshawb lub |

||||||||||

D10(um) |

D50(um) |

D90(um) |

||||||||||||||

JCF1-1 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.2 |

≥4.0 |

0.5-1.0 |

≤3 |

3.0-5.0 |

|||||||

JCF1-2 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.9 |

0.6-1.5 |

2.0-3.0 |

4.5-8.0 |

|||||||

JCF1-3 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.8 |

1.0-3.0 |

3.0-5.0 |

5.0-12.0 |

|||||||

JCF1-4 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

1.5-3.5 |

5.0-6.0 |

11.5-16.5 |

|||||||

JCF1-5 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.0-4.0 |

≥6 |

12-20 |

|||||||

JCF1-6 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥4.0 |

1.5-2.5 |

3.0-4.0 |

5.5-8.5 |

|||||||

JCF1-7 |

≥98 |

≤0.80 |

≤0.70 |

≤0.4 |

≥2.5 |

≥4.0 |

2.0-3.5 |

4.0-5.0 |

7.0-11.0 |

|||||||

JCF1-8 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.5-4.0 |

5.0-6.0 |

11.5-14.5 |

|||||||

Cov los rau hauv lawm(%) |

Tsis cov xovxwm physical |

|||||||||||||||

Fe% |

C% |

N% |

O% |

AD(g/cm³) |

Tap Density |

Laser Size Tshawb lub |

||||||||||

D10(um) |

D50(um) |

D90(um) |

||||||||||||||

JCF1-1 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.2 |

≥4.0 |

0.5-1.0 |

≤3 |

3.0-5.0 |

|||||||

JCF1-2 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.9 |

0.6-1.5 |

2.0-3.0 |

4.5-8.0 |

|||||||

JCF1-3 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.8 |

1.0-3.0 |

3.0-5.0 |

5.0-12.0 |

|||||||

JCF1-4 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

1.5-3.5 |

5.0-6.0 |

11.5-16.5 |

|||||||

JCF1-5 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.0-4.0 |

≥6 |

12-20 |

|||||||

JCF1-6 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥4.0 |

1.5-2.5 |

3.0-4.0 |

5.5-8.5 |

|||||||

JCF1-7 |

≥98 |

≤0.80 |

≤0.70 |

≤0.4 |

≥2.5 |

≥4.0 |

2.0-3.5 |

4.0-5.0 |

7.0-11.0 |

|||||||

JCF1-8 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.5-4.0 |

5.0-6.0 |

11.5-14.5 |

|||||||

Cov los rau hauv lawm(%) |

Tsis cov xovxwm physical |

|||||||||||||||

Fe% |

C% |

N% |

O% |

AD(g/cm³) |

Tap Density |

Laser Size Tshawb lub |

||||||||||

D10(um) |

D50(um) |

D90(um) |

||||||||||||||

JCF1-1 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.2 |

≥4.0 |

0.5-1.0 |

≤3 |

3.0-5.0 |

|||||||

JCF1-2 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.9 |

0.6-1.5 |

2.0-3.0 |

4.5-8.0 |

|||||||

JCF1-3 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥3.8 |

1.0-3.0 |

3.0-5.0 |

5.0-12.0 |

|||||||

JCF1-4 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

1.5-3.5 |

5.0-6.0 |

11.5-16.5 |

|||||||

JCF1-5 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.0-4.0 |

≥6 |

12-20 |

|||||||

JCF1-6 |

≥98 |

≤0.80 |

≤0.60 |

≤0.4 |

≥2.5 |

≥4.0 |

1.5-2.5 |

3.0-4.0 |

5.5-8.5 |

|||||||

JCF1-7 |

≥98 |

≤0.80 |

≤0.70 |

≤0.4 |

≥2.5 |

≥4.0 |

2.0-3.5 |

4.0-5.0 |

7.0-11.0 |

|||||||

JCF1-8 |

≥98 |

≤0.90 |

≤0.70 |

≤0.4 |

≥2.2 |

≥3.5 |

2.5-4.0 |

5.0-6.0 |

11.5-14.5 |

|||||||

· Txwm Kev Caij Peb Tsawg Lus · Ntsuam Rau Xov Xwm Nyob Qhia (Micron Primary Particle 0.1-10 μm) · Spherical Morphology · Onion-Skin Micro Structure · Txwm Cov Nyob Tawm · Txwm Pog Ntawv, Dispensability Lwm Yog Hais Tsis Muaj.

2. Q: Koj factory nyob qhov twg? Koj paub koj mus thiaj?

A: Lub factory nyob rau Laiwu district, Jinan city, Shandong Province, China. Koj paub mus rau Shanghai tej thiab mus rau koj rau hauv tus tswj kev, los yog koj paub mus rau hauv Jinan city thiab koj mus rau hauv lub heli coj thiab lub high speed train station.

3. Q: Koj paub koj mus rau hauv kev pab?

A: TT thiab LC

4. Q: Koj paub koj mus rau hauv kev sample thiab mus tom pom?

A: Yog lawv tawj thiab, mus txog qhia los yog tau, ntawd lub hauv rau kawg li xav tau, koj yuav tsum ua rau koj. Koj yuav tsum ua rau koj hais tias cov ntsiag nyob rau koj, koj yuav tsum ua rau koj hais tias cov ntsiag nyob rau koj, koj yuav tsum ua rau koj hais tias cov ntsiag nyob rau koj.

5. Q: Koj muaj kev quality control system?

Q: Kuv tias cov nyob rau hais tsev ua hauj ib tug nrog lub tsis ntawm, thiab kuv tias cov ntsuam nqi ntawm raws li cas los ntawm qhov kev cai. Kuv yog cov ntsuam nqi ntawm raws li cas los ntawm ISO thiab IATF16949.

6. Q: Peb yuav tsum mus qhia rau?

A: 100grams.

7. Q: Ntawv tau:

A: Lub ntawv yog muaj rau ndawg. Yog koj muaj txog qhia los yog koj muaj txog qhia los yog koj muaj txog qhia. Los yog koj muaj txog qhia, thaum koj pab qhia, thaum koj pab qhia.

Tsis tom qhia los yog koj muaj txog qhia los yog koj muaj txog qhia.

Kuv tsis muaj txog qhia los yog tau, ntawd lub hauv rau kawg li xav tau, koj yuav tsum ua rau koj. Yog koj muaj tej kev pab, koj yuav tsum ua rau koj hais tias Email, WeChat, Skype, WhatsApp, los yog Phone call.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. Yog peb caij mus rau kawg - Kev Ceeb Toom Siab