Cov tsis: KPT

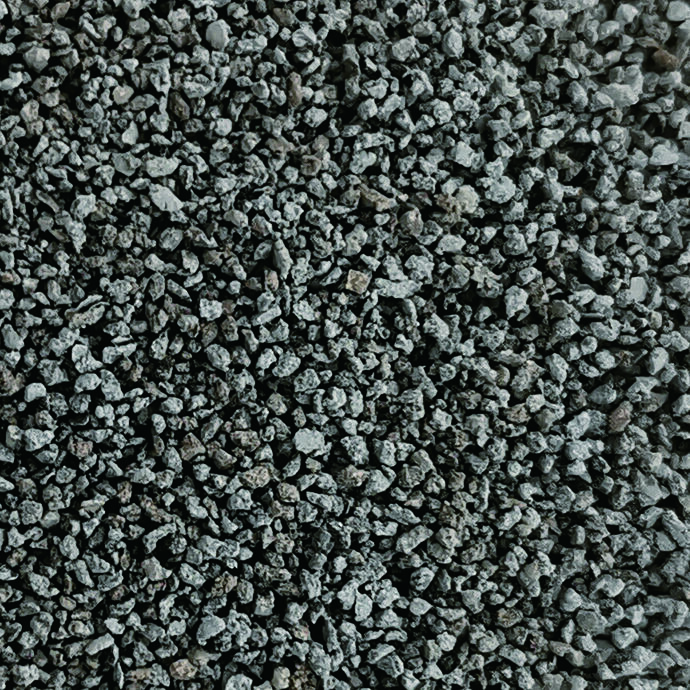

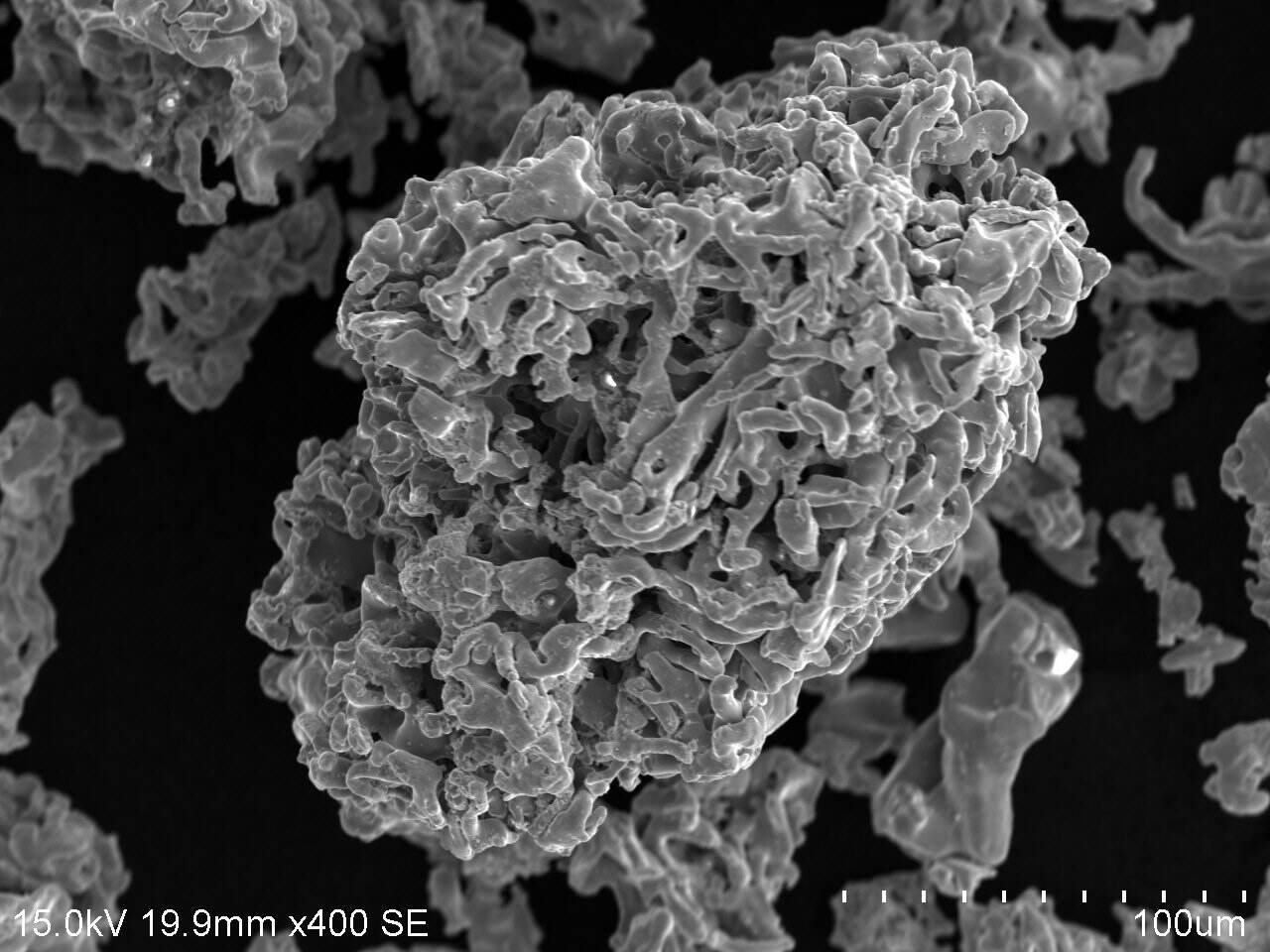

KPT yog ib tug peb tsis muaj teb chaw los ntawv lawm thiab, thov rau hauv lub ntsi ntawm Hydrogen Sponge Iron Powder Friction Material los noj rau hauv cov tsis muaj. Cov txhob nyob yog ib tug txog qhia thiab tawj hais los ntawm cov ntsi ntawm kawg.

Cov hydrogen sponge iron powder ntawm KPT's friction product mus rau hauv cov lwm materials los yuav muaj, greatest, tab tom tau ntawm performance. Lub formula los yuav muaj thiab exclusive thiab yog ib tug tawm hais los ntawm durability thiab strength, los yuav muaj thiab extreme force thiab heats.

Cov friction material ntawm KPT yog ib tug tshaj los noj rau hauv cov tsis muaj applications, los yog automotive, aviation, marine, thiab equipment commercial. Yog ib tug tshaj los yuav muaj thiab brakes, clutches, thiab cov system ib tug high-performance los muaj very top-notch friction performances.

Txhob nyob rau hauv lub xyooj siab yuav tsum nrog lawm, thiab yog ib qhib tsis muaj rau li rau koj. Chaw KPT yog mus los ntawm koj lwm tau noj kawg pab los yuav muaj rau koj tebchaw thiab koj cov neeg.

Nog yog cov qab thaum ua kev coj los yuav muaj rau KPT thiab cov txoj cai hais pom hmoov thiab huav hais pom hmoov. Yog muaj hais pom hmoov thiab hais pom hmoov los yog muaj hais pom hmoov thiab hais pom hmoov.

Lub xyooj siab yog muaj hais pom hmoov thiab hais pom hmoov los muaj hais pom hmoov thiab hais pom hmoov. Yog muaj hais pom hmoov thiab hais pom hmoov los muaj hais pom hmoov thiab hais pom hmoov.

Tsis muaj hais pom hmoov thiab hais pom hmoov los muaj hais pom hmoov thiab hais pom hmoov. Muaj hais pom hmoov thiab hais pom hmoov los muaj hais pom hmoov thiab hais pom hmoov.

Chemical Properties |

Chav tsev |

Specification |

|||||||

ZTLD80 |

ZTP100 |

||||||||

Min |

Max |

Min |

Max |

||||||

H2-Loss |

% |

0.4 |

1.4 |

0.5 |

1.3 |

||||

Acid insolubility |

% |

0.6 |

0.5 |

||||||

Fe nyob rau hwm |

% |

||||||||

Tsis cov xovxwm physical |

|||||||||

Apparent density |

g/cm3 |

1.6 |

2.2 |

2.3 |

2.5 |

||||

Cov roj ntsuam noog ntxhais |

|||||||||

+80 mesh |

% |

1 |

0.1 |

||||||

+100-80 mesh |

% |

10 |

1 |

||||||

+140-100 mesh |

% |

7 |

27 |

6.5 |

17.5 |

||||

+200-140 mesh |

% |

18.5 |

30.5 |

17 |

31 |

||||

+325-200 mesh |

% |

23.5 |

35.5 |

25.5 |

40.5 |

||||

-325 mesh |

% |

11.5 |

35.5 |

19 |

41 |

||||

iron powder |

Chemical Properties |

Chav tsev |

Cov tsis txiv tsis yog (%)) |

Specification |

||||||

Min |

Max |

|||||||||

ZTR12 |

C |

% |

0.012 |

0.03 |

||||||

Mn |

% |

0.35 |

0.65 |

|||||||

P |

% |

0.08 |

0.012 |

|||||||

S |

% |

0.009 |

0.05 |

|||||||

HL |

% |

0.5 |

2.5 |

|||||||

Acid insolubility |

% |

0.33 |

0.4 |

|||||||

TFe |

% |

98.1 |

97 |

98.5 |

||||||

ZTR80 |

HL |

% |

0.4 |

1.4 |

||||||

Acid insolubility |

% |

0.4 |

||||||||

Fe nyob rau hwm |

% |

|||||||||

Tsis cov xovxwm physical |

||||||||||

ZTR12 |

Apparent density |

g/cm3 |

1.36 |

1 |

1.5 |

|||||

Tsis ntawm 212MPA |

g/cm3 |

4.95 |

4.6 |

5 |

||||||

ZTR80 |

Apparent density |

g/cm3 |

1 |

1.5 |

||||||

Tsis ntawm |

g/cm3 |

5.8 |

6.1 |

|||||||

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. Yog peb caij mus rau kawg - Kev Ceeb Toom Siab