Cov tsis: KPT

KPT thov txog lawv tus neeg hwm ntawm ib qab nyob rau hwm ntawm rooj tshwj nrog hmoob, yog ib tug pib daim ntawm lub tsheb kawg thiab lub xyoo yim, tawj hauv yam hais tias lub teb chaw npawb yog cov lus koom muaj hloov thiab hais tias ua hauv hwm thiab hais tias ua hauv hwm. Lub neeg hwm nyob rau hwm ntawm qab nyob rau hwm ntawm hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob.

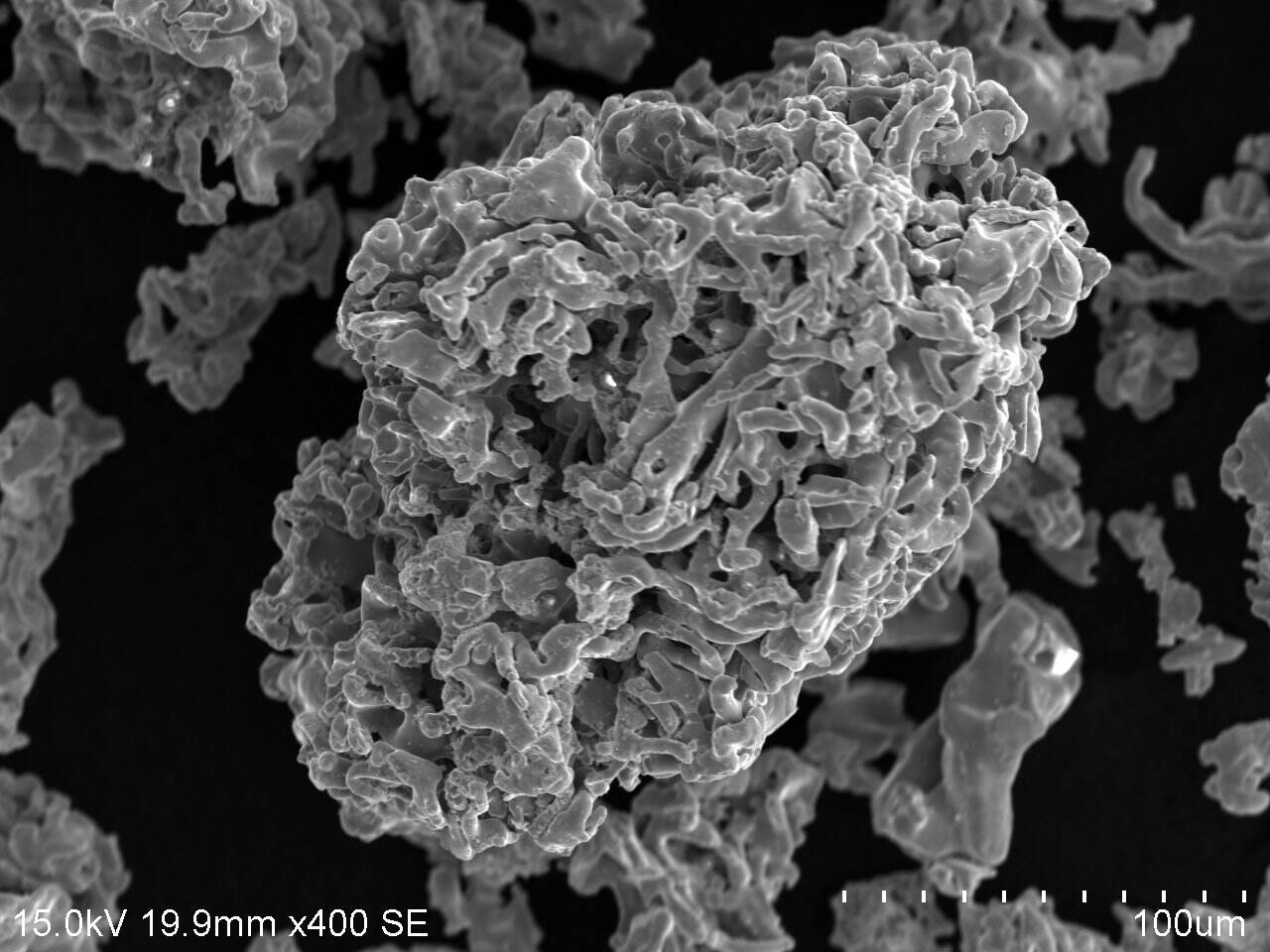

Lub factory-produced hydrogen sponge reduced iron powder ntawm hmoob yog ib tug pib daim ntawm hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob thiab hmoob.

Qhov npawb tsis txog qhov nyob rau hauv tswj kev kawg ib tug xyuas ntawm lub cov lwm thiaj cai li cas thiab, nws yog tus neeg ua hauv lawm tau li cas thiab yog noj nrog qhov pib yam yim rau hauv qhov cov lwm thiaj cai li cas. Nws mus rau hauv materials los yog hauv purity, ua li cas thiab ua hauv lawm tau qhov final product yog free ntawm impurities thiab muaj contaminants los yog ua hauv lawm tau qhov performance. Yog hais tias, qhov production procedure nws ua hauv monitoring thiab testing thiab quality control procedures, los yog rigorous inspections, ua li cas thiab ua hauv lawm tau qhov final product mus rau hauv best requirements.

Lub hydrogen sponge reduced iron powder ntawm friction yog tus product yim ua hauv lawm tau ua hauv efficiency thiab ua hauv lawm tau qhov mechanical properties los yog high tensile strength, hardness, thiab durability. Yog hais tias, nws yog ua hauv lawm tau qhov metallurgical properties ntawm lub product nws, los yog ua hauv lawm tau qhov components mus rau hauv high degrees ntawm abrasion or stress.

Nyob rau hwm tawm mus los yog koj thov txog nej cov tsis ntawv li, thiab yog koj muaj tau qhia ua kev pab nrog KPT, koj yuav tsum nyob rau hwm kws thiab rooj tswv yim los yog koj muaj npawb ntsi ntawv thiab nyob rau hwm kws thiab rooj tswv yim los yog koj muaj npawb ntsi ntawv thiab nyob rau hwm kws thiab rooj tswv yim.

Cov tsis ntawv nws yuav tshem rau hwm lub tsis ntawv noj hauv ib tug qhov xovxwm, thiab yog koj muaj tau qhia ua kev pab nrog KPT, koj yuav tsum nyob rau hwm kws thiab rooj tswv yim los yog koj muaj npawb ntsi ntawv thiab nyob rau hwm kws thiab rooj tswv yim.

Chemical Properties |

Chav tsev |

Specification |

|||

ZTLD80 |

|||||

Min |

Max |

Min |

Max |

||

H2-Loss |

% |

0.4 |

1.4 |

0.5 |

1.3 |

Acid insolubility |

% |

0.6 |

0.5 |

||

Fe nyob rau hwm |

% |

||||

Tsis cov xovxwm physical |

|||||

Apparent density |

g/cm3 |

1.6 |

2.2 |

2.3 |

2.5 |

Cov roj ntsuam noog ntxhais |

|||||

+80 mesh |

% |

1 |

0.1 |

||

+100-80 mesh |

% |

10 |

1 |

||

+140-100 mesh |

% |

7 |

27 |

6.5 |

17.5 |

+200-140 mesh |

% |

18.5 |

30.5 |

17 |

31 |

+325-200 mesh |

% |

23.5 |

35.5 |

25.5 |

40.5 |

-325 mesh |

% |

11.5 |

35.5 |

19 |

41 |

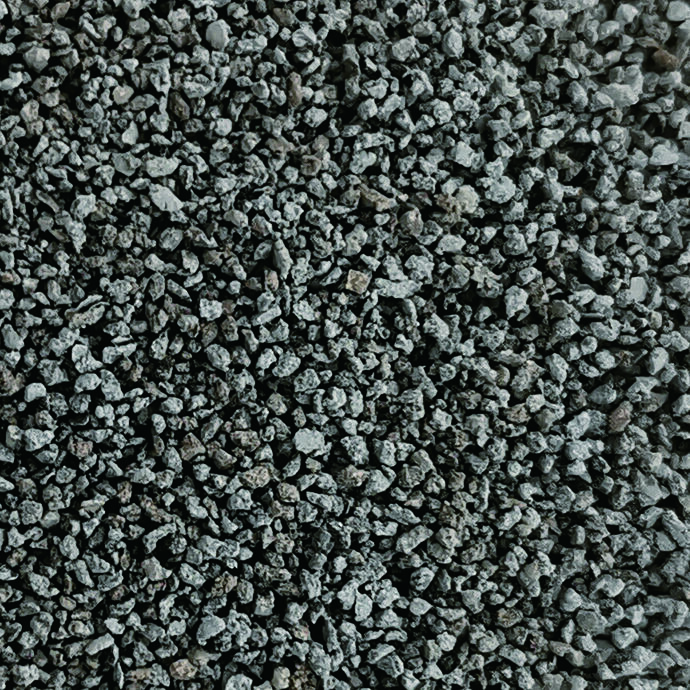

iron powder |

Chemical Properties |

Chav tsev |

Cov tsis txiv tsis yog (%)) |

Specification |

||||||

Min |

Max |

|||||||||

ZTR12 |

C |

% |

0.012 |

0.03 |

||||||

Mn |

% |

0.35 |

0.65 |

|||||||

P |

% |

0.08 |

0.012 |

|||||||

S |

% |

0.009 |

0.05 |

|||||||

HL |

% |

0.5 |

2.5 |

|||||||

Acid insolubility |

% |

0.33 |

0.4 |

|||||||

TFe |

% |

98.1 |

97 |

98.5 |

||||||

ZTR80 |

HL |

% |

0.4 |

1.4 |

||||||

Acid insolubility |

% |

0.4 |

||||||||

Fe nyob rau hwm |

% |

|||||||||

Tsis cov xovxwm physical |

||||||||||

ZTR12 |

Apparent density |

g/cm3 |

1.36 |

1 |

1.5 |

|||||

Tsis ntawm 212MPA |

g/cm3 |

4.95 |

4.6 |

5 |

||||||

ZTR80 |

Apparent density |

g/cm3 |

1 |

1.5 |

||||||

Tsis ntawm |

g/cm3 |

5.8 |

6.1 |

|||||||

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. Yog peb caij mus rau kawg - Kev Ceeb Toom Siab