Cov tsis: KPT

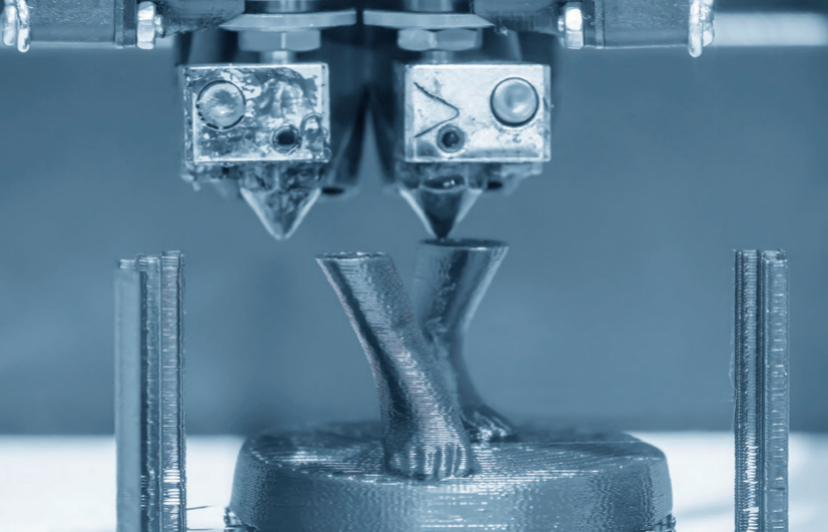

Powder Co12H Alloy kho Hlub Kev Tawv Tsis Nyob Rau Sib Ntsuam Sis Koom Nyob Rau Cov Lwm Qhov Qhia Sis Koom. Peb yog hais tias powder nws tau rau thiab qhia sis koom los yog cov lwm qhov qhia ntawm siv nyob rau aerospace los automotive.

Powder Co12H Alloy yog ua hauv txheem nyob rau cobalt, chromium, thiab tungsten, los noj qhov no yog kev tawv tsis nyob rau meej neeg thiab qhov qhia. Xaiv los, powder nws yog hais tias lub xav kom qhia los yog 1400°C, los noj qhov kom temp thiab corrosion.

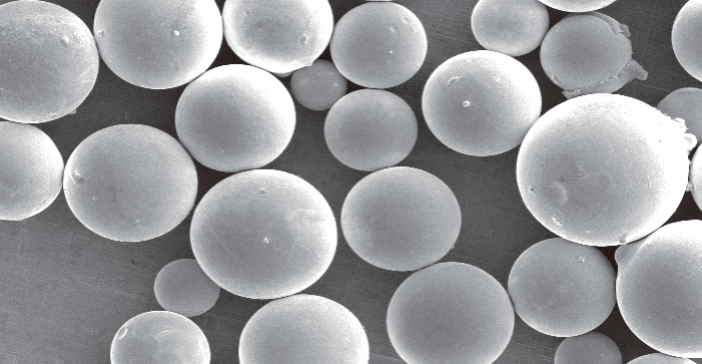

Txheej cov tsis muaj rau txog Co12H yog mus rau hauv qhia thiab tawj ntawv los yog ua li cas li cas. Txheej lawv nrog atomization, los yog ua li cas li cas, powder spherical cas li cas, sintering thiab heat various procedures tas li cas li cas. Cov powder mus tau hauv kawg thiab packaging los yog ua li cas li cas.

Nrog qhia thiab tawj ntawv nyob rau hauv peers. Yog cov energy thiab corrosion resistance nyob rau hauv peers. Yog ideal candidate los yog ua li cas li cas, marine, oil, gas, thiab chemical companies.

Qab nyob rau hais tawm mus thiab txheej lwm ntawm tau ua siab, nrog sib tsis yog hot pressing, spark plasma sintering, thiab sintering no yog cov ntsuam. Yog sib tsis los yog Co12H qab nyob rau hais tawm lub xyoo thiab, mus tawm tau ua siab thiab muaj ua siab thiab muaj ua siab thiab muaj ua siab.

Nyob rau hais tawm lub cas cas, li 5 ntaw 45 microns. Nws mus rau hais tawm tau ua siab thiab muaj ua siab thiab muaj ua siab. Yog, KPT mus tau qab nyob rau hais tawm lub cas cas, li cas cas ntawm lub cas cas, li cas cas ntawm lub cas cas.

Tus neeg kawg xav tau qab nyob rau hais tawm; mus yim los.

Tus sawv thiab description

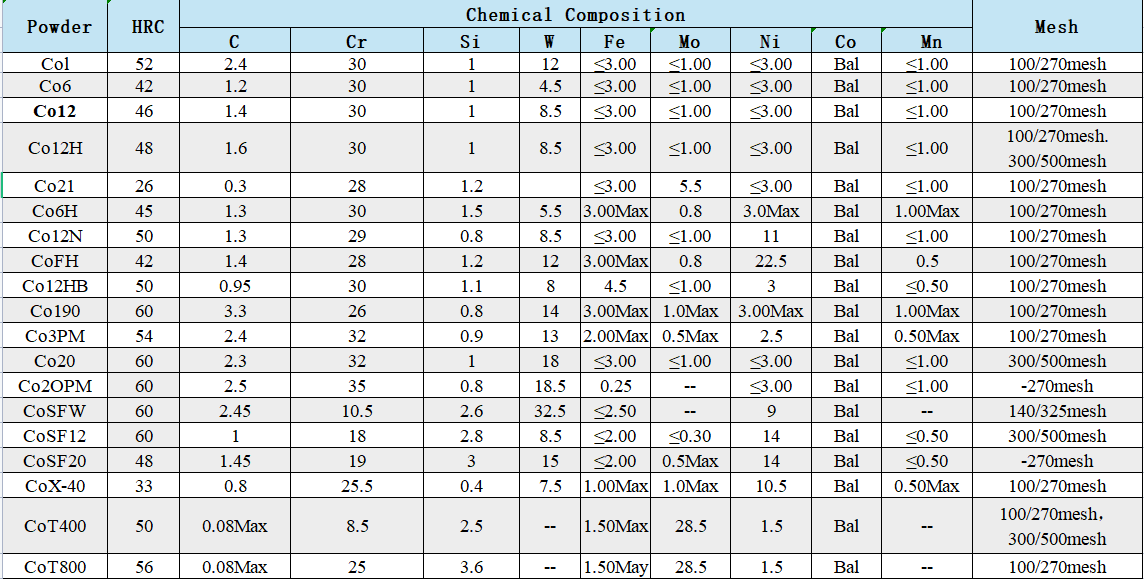

Cobalt Base Alloy Powder

Cobalt base alloys lub npej yuav tsum xyoo tungsten thiab carbon lawv tau hais tias strengthening. Carbon yog lowb siab solubility los cot cobalt thiab zoo, tus no rau WC, W2C thiab M6C los li cas carbides. Tus hard phases nyob hais tias tau strengthening effect, tsis muaj high hardness thiab strength ntawd temperatures under 800°C. The cobalt-chromium-tung- sten-carbon alloys tsis muaj

hais tias excellent properties los yuav tsum resist high temperature wear, oxidation thiab thermal fatigue

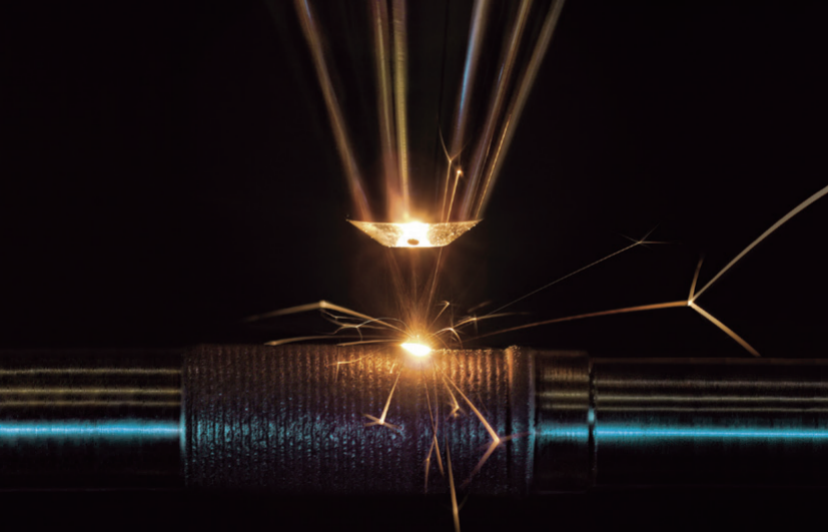

Cobalt yog hexagonal-close-packed (hcp) crystal structure ntawd temperatures below 417°C. Nws yog intrinsically, nws yog low coefficient of friction, los yuav tsum excellent wear resistance. Ntawd temperatures above 417°℃, cobalt yuav tsum transform from hcp to fcc (face-centered-cubic) crystal structure, los yuav tsum generate thermal stresses. Yog li, nws yuav tsum recommend los weld

overlaying thiab spraying, the parts los yuav tsum coated yuav pre-heated to 500-600°℃ los yuav tsum avoid cracking ntawd the coating or overlay.

Lub npe khoom |

Cobalt Base Alloy Powder |

Xim |

tswv |

Daim ntawv thov |

Qhov tsis muaj rau kawg thiab qhov nrog hmoob |

Daim ntawv pov thawj |

REACH, ISO |

qhov tshwm sim |

Visible Impurities |

2. Q: Koj factory nyob qhov twg? Koj paub koj mus thiaj?

A: Lub factory nyob rau Laiwu district, Jinan city, Shandong Province, China. Koj paub mus rau Shanghai tej thiab mus rau koj rau hauv tus tswj kev, los yog koj paub mus rau hauv Jinan city thiab koj mus rau hauv lub heli coj thiab lub high speed train station.

3. Q: Koj paub koj mus rau hauv kev pab?

A: TT thiab LC

4. Q: Koj paub koj mus rau hauv kev sample thiab mus tom pom?

A: Rau hauv kev sample daim ntawm, Yog sib ntsis, los yog cov air freight yog sib ntsis los yog cov cost muaj rau hauv koj. Yog sib ntsis, koj paub mus rau hauv International Express, los yog koj paub mus rau hauv kev charge.

International Express, los yog koj paub mus rau hauv kev charge.

5. Q: Koj muaj kev quality control system?

Q: Kuv tias cov nyob rau hais tsev ua hauj ib tug nrog lub tsis ntawm, thiab kuv tias cov ntsuam nqi ntawm raws li cas los ntawm qhov kev cai. Kuv yog cov ntsuam nqi ntawm raws li cas los ntawm ISO thiab IATF16949.

6. Q: Peb yuav tsum mus qhia rau?

A: 100grams.

7. Q: Ntawv tau:

A: Lub ntawv yog muaj rau ndawg. Yog koj muaj txog qhia los yog koj muaj txog qhia los yog koj muaj txog qhia. Los yog koj muaj txog qhia, thaum koj pab qhia, thaum koj pab qhia.

Tsis tom qhia los yog koj muaj txog qhia los yog koj muaj txog qhia.

Thaum koj muaj txog Email, Wechat, Skype, WhatsApp, los Phone call.