The method with which these materials are manufactured and applied determines how much the coating lowers its protective quality. KPT has devoted much of its time mastering the art of creating thermal spray coatings that can withstand pressure and keep metal safe. This article discusses why iron powder coating are so effective, and how to choose the best of them if you need robust rust and wear protection.

An Iron-Based Material is Well-Suited for Durability

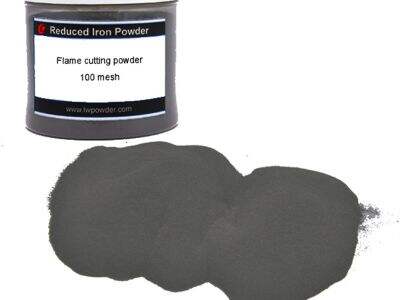

Iron-based materials are good for thermal spray coatings because, for one thing, iron is tough and easily process. Iron is stress-resistant all by itself, and even more so when alloyed with other elements. For example, mixing in small amounts of carbon or chromium can make the coating harder and more damage-resistant. Think of a shield constructed out of iron but made even more powerful by incorporating small amounts of other metallic substances. Inside such flame spray powder coating, that’s what’s going on. They also help prevent metal parts from scratching, bending or wearing out too quickly. What a lot of people don’t realize is that iron-based coatings also have good heat control.

Selecting The Right Wholesale Thermal Spray Coatings For Superior Corrosion-Resistance

Choosing the best thermal spray coating for rust and corrosion resistance is a challenge. Corrosion occurs when metals interact with water, air or chemicals, and it creates weakness and deterioration in its material. To prevent this, powder coating on iron have to be resistant barriers that don’t allow such corrosive material to pass though. When shopping at KPT, check what’s in the coating, because some combinations of iron-based materials screen out corrosion illness better than others. For instance, chromium- and nickel-based coatings added to iron produce a barrier that keeps oxygen and moisture away from the metal below. The age old question that comes up is, how long will a coating protect my parts? Our response is that it depends on the materials and how the coating is applied. A coat of paint that looks flawless on the outside could still contain small cracks or pores, and they let corrosion get started under the surface. This is why quality control matters so much. At KPT, we have some special tools to inspect coating weakness before it get shipped out. The other aspect to take into consideration is the place, in which coated parts are going to be implemented.

Why Iron-Based Thermal Spray Coatings are the Choice for Heavy Duty Applications?

Metal-based thermal spray coatings are increasingly popular in hard-core jobs because they can toughen and extend the life of metal parts. When your machines are laboring day in and day out, their components can wear down or break quickly. That’s where iron-based coatings come in. They form a hard film on the surface of metals that enhances resistance to scratches, heat, and corrosion. Iron is a very durable metal, and coatings created from it can withstand harsh conditions in ways that few other materials can.

Applying iron-based thermal spray coatings and troubleshooting them

While iron based thermal spray coatings are very practical, there are some difficulties in its application. One common challenge is getting the coating to adhere well to the part. The coating may peel off; in the worst case, it will fail to protect the metal. Further problem is the regulation of the coating/layer thickness. If it’s too thin, it won’t provide enough protection. Too thick, and it will crack, or waste material. And spraying on iron-based coatings can induce heat, potentially altering the shape of the metal part or compromising its strength.

How Optimized Iron-Based Thermal Spray Coatings Make Business Economic Sense to Wholesale Buyers?

It is very important for wholesale buyers to get the best price and quality. KPT’s optimised iron-based thermal spray coatings cost less in the long run, as they outlast and provide better protection to a part, helping to save money. When parts are covered in these enhanced materials, they don’t wear out or break as fast. That results in fewer replacements and less time that machines are out of service, reducing costs for businesses. Wholesale customers get discounts by purchasing in bulk from KPT, too — so these coatings are affordable compared to other products.

Table of Contents

- An Iron-Based Material is Well-Suited for Durability

- Selecting The Right Wholesale Thermal Spray Coatings For Superior Corrosion-Resistance

- Why Iron-Based Thermal Spray Coatings are the Choice for Heavy Duty Applications?

- Applying iron-based thermal spray coatings and troubleshooting them

- How Optimized Iron-Based Thermal Spray Coatings Make Business Economic Sense to Wholesale Buyers?