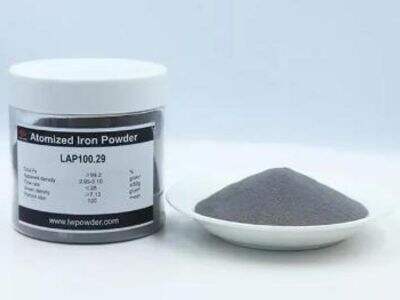

Friction materials are crucial in machines and vehicles, as they stop or slow down moving parts. When two surfaces are brushed against each other, friction is the sense that makes them slow down or stop. But friction also causes parts to wear out over time. We at KPT Have been working hard to enhance the performance of Friction material making it more durable With the best possible Penetration By Utilizing special Iron Powders. This is no ordinary iron powder; it is customized, so produced thoughtfully to fit precisely what the friction material requires. By varying the size, shape and composition of iron powder in it, we can dictate how the material breaks down as it is used. This kind of thing makes the machine run longer, and it saves money because then you don’t have to replace parts as often. It’s sort of like if you gave friction materials a smart grade that would help them do their job rather than die too quickly

Friction materials modified by special iron powder for high wear resistance is a big leap. Wear resistance is the capability to withstand rubbing and scraping without serious damage. When prepared to just the right size for friction materials, iron powder helps them all remain strong and long-lasting. If that iron powder, for instance, is too rough or soft the material could break down to quickly or not stop things properly. KPT_opt uses iron powder calibrated to the right combination of hardness and smoothness. This magical powder acts like microscopic shields within the friction material. When the fabric rubs, these little shields absorb the brunt of it and preserving the rest. They prevent the material from splitting or hollowing out. And the way iron powder hugs inside the friction material can influence where heat gets distributed when things are rubbing quickly. Heat can also accelerate wear and tear of parts, but specially designed powder helps keep things cool by distributing heat more evenly. Machines are freer to work harder, thanks to that; and then they can double-shift without trouble. We have seen that the use of friction materials containing KPT’s custom iron powder can tackle challenging work, even in car brakes and big factory machines, yet remain strong after many uses. This is not just about making something tougher; it’s about making things smarter, because we don’t have to spend so much time realizing and retesting our mistakes

How Customized Iron Powder Enhances Wholesale Performance Of Friction Supplies

Wholesale means creating lots of friction materials for many different customers, typically, different machines or vehicles. Every customer may desire something a bit different, such as materials that function better in cold places or for heavy loads. KPT’s custom iron powder can easily be modified to satisfy these varying requirements. These materials have the potential for coordinating adjustable rates of wear by altering properties of the iron powder, making friction materials where we can dial-in wear, not too high and not too low. That controlled wearing means customers will receive products that last just as long as they should in their machines. For instance, a company that manufactures brakes for delivery trucks would require materials that can halt heavy loads but not wear out quickly. The startup develops custom iron powder with KPT to help them achieve longer lasting and more consistent materials. This means less downtime and lower maintenance costs. Also, as the iron powder is prepared carefully, the quality of the friction materials becomes more unified. That means every batch is going to function the same way, which is of paramount importance when you are doing large orders. Hiani: Based on my experience at KPT, our customers like these kind of materials, because they help them save money and make their machines safer. Beat that with a steam iron: Tailored iron powder isn’t just small change; it’s an intelligent choice with major real-world impacts

Why is Specially Prepared Iron Powder Needed to Control Wear Performance of a Brake Lining

Friction materials are a critical part of many machines and vehicles because they help to slow or stop moving parts. Friction occurs when two things rub against each other. This creates heat and scratches off little pieces of the material, which can make parts stop working well as they rub against one another over time. To extend the life and improve the functioning of these materials, one must control how they wear out. One way to accomplish this is by deploying iron powder that’s specifically designed for the task at hand: so-called tailored iron powder. At KPT we produce customized iron powders which meet the specification of various friction materials. Tombale points out that such powders are the correct size, shape, and hardness to be useful in combatting wear. The significance of this is that the behavior of friction materials during operation can be altered by tailored iron powder. For instance, if the iron powder is too soft, it could erode more rapidly over time. If it is too stiff, it will be more likely to damage the other parts that it comes into contact with. Making the iron powder just so allows KPT to help friction materials wear smoothly and gradually. This is why the parts last longer and work better. In addition, the iron powder specific for use in processing is used to stabilize temperature of a friction portion at time of use. The parts degrade more quickly when they get too hot. The iron powder provides the means for removing that heat and so insulates the friction pad from becoming overheated. This is a second way it manages wear. Simply put, KPT's customized iron powder is a necessity as it functions in the capacity of a helper in friction materials. It regulates how rapidly materials erode and how long they stay in good shape. If the iron powder isn’t right, friction materials could wear out too quickly, or wreak havoc in the machines they are being used in

CONTROLLED WEAR WITH TAILORED IRON POWDER BRINGS IMPROVED FRICTION MATERIAL LIFE

Friction materials that wear in a predictable manner last longer and perform better. That means machines and vehicles can be safer, and need less fixing. KPT’S customized iron powder is very much involved in suppressing the wear of friction materials on a slow, uniform basis. Material does not break or become dislodged even when wear behavior is controlled. Instead, it holds and does its job for a long time. This is called durability. Durability is very important since friction materials are used in products as varied as car brakes, clutches and many other applications where safety and performance are critical. If the brake pad material wears too quickly, accidents can occur or be expensive to replace. KPT iron powder controls wear by providing a smooth and stable friction surface. This also means there are fewer rough spots that can break parts. The iron powder also cools the friction material, preventing it from weakening or cracking. It doesn't wilt or soften when it's cooler. This helps make it durable for long-lasting use. A second approach in which KPT’s customized iron powder adds durability is to help the friction material wear at the proper rate. If it doesn’t wear quickly enough, it could generate too much heat or make the machine work harder. If it goes on too quickly, the parts wear out fast. Finding the right iron powder is about striking a balance, so that the friction material delivers great performance but doesn’t wear out too quickly. This controlled wear also maintains the cleanliness of the parts of the machine. But when materials wear out too quickly, small fragments can become lodged where they are not wanted and cause harm. But when it comes to KPT’s iron powder, the wear is flat, so there is less dirt and less trouble. Designed to deliver predictable wear rates, KPT’s custom iron powder results in friction materials that last longer, perform better and are gentler on machines. This is no small matter for people who work with equipment or vehicles every day

What Purchasers Should Know about customized ferrous powder for optimization of friction materials

If you're in the market for a friction material or products that contain friction materials, it is essential to know first-hand how customized iron powder can be beneficial to these resources. Special iron powders to improve and extend the life of friction materials is what we do at KPT. Buyers can ask such questions when selecting the friction product: Does the product incorporate customized iron powder and in what way does it help manage wear behavior? This is because iron powders are not created equal. Some may wear too soon or create other issues in the material. KPT’s iron powders are produced with exacting control over factors like powder size, shape and strength. This makes them adjustable to the specific requirements of the friction material and machine in which it will be used. Buyers, should also take note that saving money can definitely be achieved when using friction materials that incorporate tailored iron powder. Even if its upfront cost is initially higher, the longer lifespan and superior performance result in fewer replacements and repairs. This saves time, money and keeps machines humming along without a hiccup

Table of Contents

- How Customized Iron Powder Enhances Wholesale Performance Of Friction Supplies

- Why is Specially Prepared Iron Powder Needed to Control Wear Performance of a Brake Lining

- CONTROLLED WEAR WITH TAILORED IRON POWDER BRINGS IMPROVED FRICTION MATERIAL LIFE

- What Purchasers Should Know about customized ferrous powder for optimization of friction materials