A large number of the properties across various different industries have silently changed since spheroidal iron powder was used as raw material. The purity of this metal is almost spherical, which is soft enough to enable the manufacturing parts used across numerous industrial process e.g. in auto part making and even electronics too. We will get there by examining some of the incredible ways this most ubiquitous material has amazed men and technology since near forebengers first started to make things from it.

Efficiency is at the root of industrial advancement. Via the utilization of spherical iron powder, some of it is made possible and contributes to low porosity as well as better flowability than non-spherical powders. Consistent particle sizes also means compaction and sintering can be done in a more even manner that, results the material density among these parts will achieve uniformity as well with high relative densification. This minimizes scrap rates which results in faster manufacturing cycles and, at the end of it all helps conserve energy when production lines are able to operate more efficiently. The round iron powder not only make the workpiece that high quality, low cost but also in favor of lean production and green manufacturing.

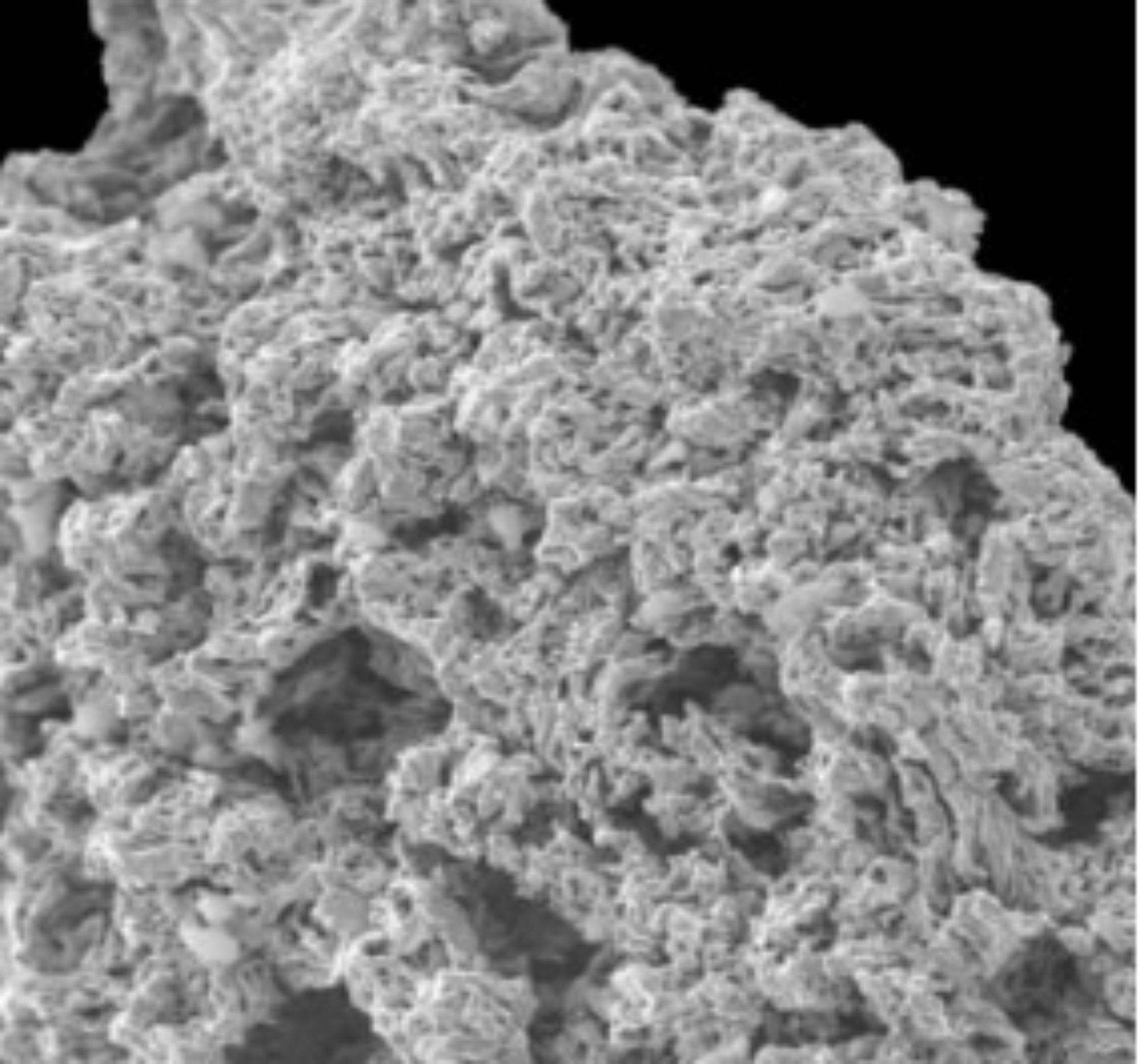

That is the wonder of a sphere of constituent metallic iron powder, brilliantly demonstrated by metal injection molding (MIM). By using ultra-pure spherical powders, MIM adds intricate detail and fine features into parts that are taking advantage of their patented microscopic pliers geometry - providing the flexibility in plastics injection moulding but with metals' strength. More geometric form complexity thanks to the introduction of a bindings agent into the powder and its amazing fluidity that can ensue, than would be possible (or at least practical) with traditional manufacturing techniques. Not only are they more densely packed, the homogeneity in these leads to them all being able sintered uniformly and to result parts that can be compared fairly well with those made of machined or cast metals - but still design freedom while remaining cost effective.

These are only can be done in Spherical Iron Powder and isotropic because it is a Sphere. This results in the unchanging property in all the directions so suitalble for ahead of time engines, transformers and generators. This results in higher efficiency energy conversion, less acoustic noise and longer magnetic device operation that promise enhanced performance of spherical iron powder. These high levels of purity are necessary not simply to remove unwanted impurities which can otherwise disrupt the magnetic fields required for steady performance in the most demanding direct current (DC) and radio frequency applications - include things like wireless charging, or data transmission etc but also offer a wide range torch magnetization values. For a cleaner future, Spherical Iron Powder in raw material form

Related articles Read more from In pictures The mandate of sustainability over all global industries now Sphere iron powder has the credentials to enable sustainable benefits throughout its life cycle. Because of that it is usually prodcued from recyceled scrap metal and not virgin iron ore which allowds signfiicantly lowest ammounts of waste to be transported. These efficiency gains also result in the corresponding lower energy consumption and emissions throughout use/application in production processes. Not only are spherical iron powder solutions generally lighter and stronger than traditional but also ensure an improved product lifecycle after they have been manufactured, resulting in a more sustainable & energy-efficient operation as well as reduced environmental footprint overall. On a global scale with nations shifting more towards models on the circular economy we are seeing an increase use of these and upcycling material.

have spherical iron powderservices for shipments and delivery. products are shipped into more than 30 countries across North America, South America, Asia, Europe have been praised by customers.We anticipate working with you become your reliable trustworthy supplier.

main business includes manufacturing metal powders. most popular products include water atomized iron powder as well sponge iron powder. hydrogen reduced sponge iron powder, low apparent density, high alloy powder, super fine iron powder stainless steel powder, carbonyl iron powder, copper powders etc.Now our company providing metal powders used in different industries, including powder metallurgy spherical iron powdertools, welding , friction materials, specifically brake pads chemicals, surface coatings, additive manufacturing ,MIM soft magnetic, water treatment soil treatment, etc.

annual capacity of KPT Company's production 200000 tonnes, and it has atomized powder sponge iron production spherical iron powder. It is the current largest company, with most complete most technologically advanced powder production company in China.

are accredited by ISO9001, SGS and REACH. KPT powder spherical iron powdercentre for province. maintain close collaboration with universities other research institutions.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy