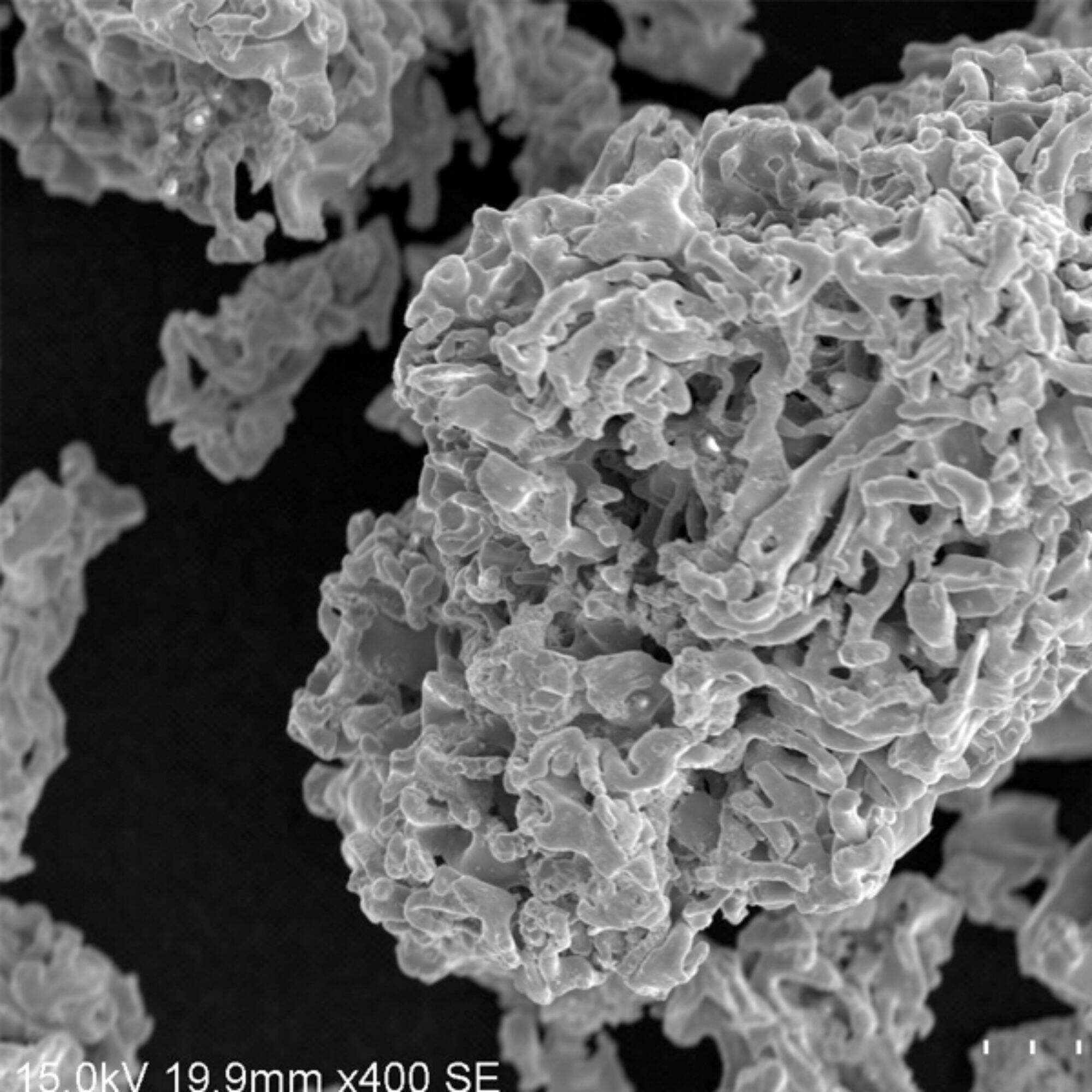

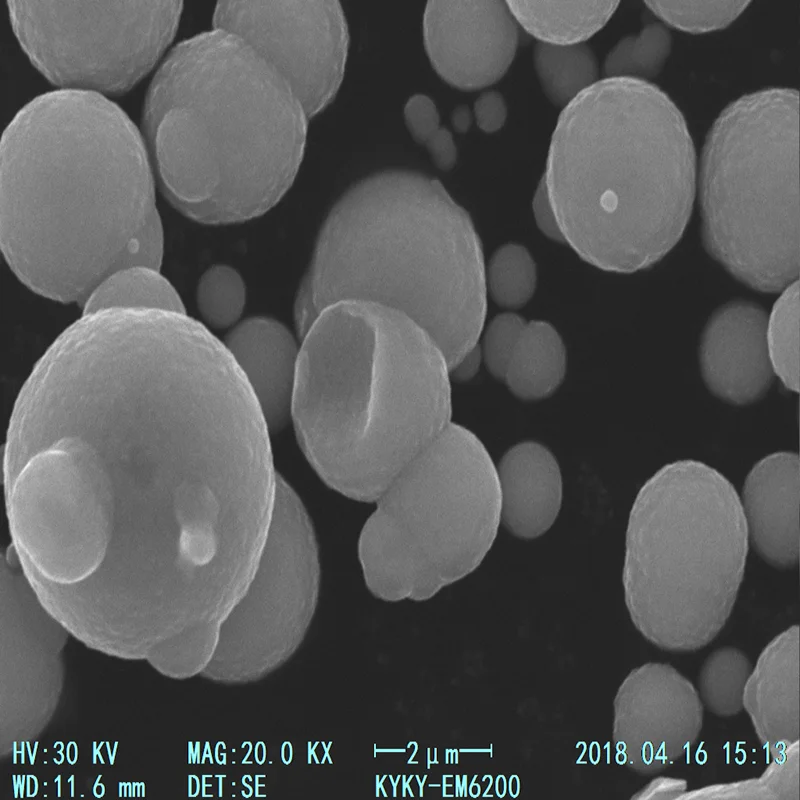

Prealloyed powder is an interesting topic and it has been produced by the atomization process (another pretty cool thing). In small size -this is done by melting metals at high temperature for the purpose of and aerodynamically gently spraying it on a surface so that incet particles consist only from metal. The powder is then filtered and screened to form a bespoke blend of alloys, the exact nature of which ProsFit has not shared.

The use of prealloyed powder is huge in this sense. Considering the consistency of prealloyed powder, you have a specific blend of metals are evenly distributed for use as base material. First, although this consistency of compositions should mean that the final products are "simple" (in comparison to) and uniform when it comes to producing them.

Innovation Patent For The Production Of Prealloyed Powder

The current gold pattern work, time prealloyed powder]%% open terrain open for type production is a confidence signal since the greatest Seit Generation - its genuity. This material, an offspring of the 21st Century has ushered in a time where complexity no longer limits one's output and creation at almost any magnitude can be achieved with tolerances to within but microns. In addition, the use of prealloyed powders has stretched these boundaries even further by allowing non-weldable parts to be manufactured.

Prealloyed powder has the outstanding advantage of increased safety during storage over other powders and also will not ignite at temperatures that would cause most ordinary metal dusts to reach their auto-ignition temperature,making dangerous industrial environments much less hazardous. But ultimately this process is carried out on a homogeneous, reproducibly the same body and thus less dangerous behind their own four walls. While prealloyed powder can be safely handled (with the right precaution), it is still a hazard.

Prealloyed powders have been used in many fields, such as food products [2] and aerospace parts [3], human body implants ganglingcomponents ]. Prealloyed puncher: Mixed with binders (usually waxes or resins) to bond the powders together before sintering. Later, the mixture is formed in a compression mold and compacting place by heating to form powder prealloy (use of the melting type as binding agent) Finally, a section of the tree was cored-out and prepared for either sandblasting or polishing.

And, in support of both prealloyed powder suppliers and their contextual processing providers. SoftenTech, LLC offers technical support, product development and custom blend-to-order services. Control high quality assurance also there is precisely prealloyed powder to stickit will have a superior level of excellence. Low cost: This unique technology can be implemented at a much lower price than the traditional methods that you are using which will increase your profit margin and save money for your industry as well.

primary business is manufacturing metal powders. We offer a diverse range products including water Prealloyed powderpowders, sponge iron hydro reduced sponge powder low apparent density, high alloy powders, super fine powders carbonyl powders as well copper powders.

have obtained certifications like ISO9001, SGS, REACH, etc. KPT the Prealloyed powderpowder metallurgy facility. maintain a close partnership universities as well other research institutions.

annual capacity of KPT Company's production 200000 tonnes, and it has atomized powder sponge iron production Prealloyed powder. It is the current largest company, with most complete most technologically advanced powder production company in China.

have strong services in terms delivery and shipping. Our products are Prealloyed powderinto over 30 countries within North America, South America, Asia, and Europe have been praised by customers.We look forward working with you to be your reliable trustworthy supplier.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy