Pig iron powder is one of the most important byproducts from production with scrap steel. It is produced by very fine powder form of Pig iron which more considered as the processing level. Reasonable fall under the limelight in almost all industries due to its extra ordinary properties and so on since it is such special material. Today, through this article we are about to explore a little more in-depth regrading pig iron powder and where these is most usable stuff like different sectors.

Another incredible advantage of pig iron powder is that it can be returned to recycling. It is reclaimed from discarded metal and thus, also serves as a reasonably-priced green alternative with regard to manufacturers. Additionally, pig iron powder is a multi-purpose material that finds application in various other industrial operations. This makes it a large industrial raw material, typically used in the production of steel (iron)clad fertilizer,straight and compositional parts for industry/ construction.

Pig Iron Powder Consumption Analysis: Pig iron powder is majorly consumed in building and construction sectors.

Pig iron powder is one of the essential basic feedstock for strengthening cement in construction and building industry. It mixes with the cement and concrete naturally to provide a strength go my construction. Apart from this, the pig iron powder is also utilized in high-performance concrete and for prefabricated components which directly shows its necessity on construction.

For example, there are advanced technologies pig iron powder influences in the automotive market for manufacturing of brake pads and steering systems components involved in engine blocks. Carbon, sielenium and manganese along with pig iron powder are blended to form this strong alloy know for its toughness wear-resistance ideally used in automotive end-users. In addition to this, pig iron powder is used in automotive industry for producing metal coatings that help prevent rust or corrosion on car bodies.

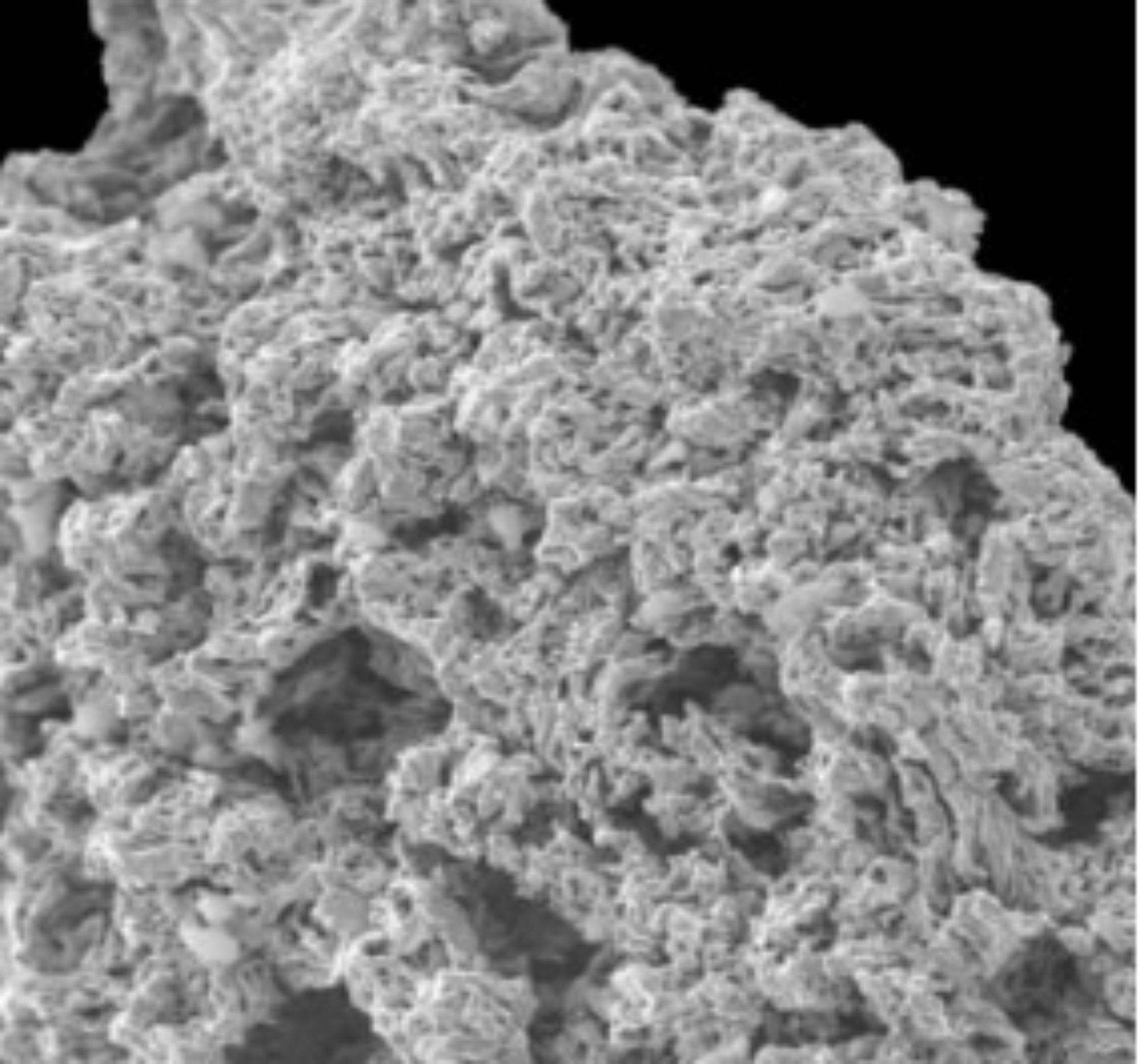

These include getting scrap from both public and private sources in order to produce the higher-grade pig iron powder. Input material is separated by type and organized. In the next step, scrap metal is placed into a high-temperature furnace where all other substances are removed and any remaining moisture. Molten metal is melted and purified, then further fine groung using extremely specialized Equipment into a powder. At the end, it'll be mixed in pig iron powder to make for easy distribution and will available as per industries requirement.

Pig iron powder is used in all sectors, besides its industrial purpose. It can be utilized as a soil amendment in agriculture for enhancing iron content of the plants. Added to all this, pig iron powder also entails making fertilizers which helps the agriculture sector function better. It is also a key ingredient in the manufacture of iron oxide pigments that are inserted into paints, coatings and plastics to colour them.

In manufacturing, pig iron powder becomes an option to consider for sectors looking to reduce costs while maintaining quality. Due to this blend of low cost (from the recycling stream, iron-containing refuse materials or scrap) and coming from a high-money value end-use product family pig iron powder can be sound solution for economies of industries looking to redraw their finances at reduced maintenance fees (or even with better quality requirements preserved).

So, in a word the pig iron powder is seen as sustainable development and ideal raw material for substituting basic metallurgical that has been changing in industrial production after all. A preferred choice of the industry by those aiming at sustainability and greener alternatives due to its recycled, durable quality as well as cost-effective metal. With the rapid development of pig iron powder, we can almost all generally agree with that however our future is going to borne as far by industrial manufacturing.

main business includes manufacturing metal powders. most popular products include water atomized iron powder as well sponge iron powder. hydrogen reduced sponge iron powder, low apparent density, high alloy powder, super fine iron powder stainless steel powder, carbonyl iron powder, copper powders etc.Now our company providing metal powders used in different industries, including powder metallurgy pig iron powdertools, welding , friction materials, specifically brake pads chemicals, surface coatings, additive manufacturing ,MIM soft magnetic, water treatment soil treatment, etc.

are accredited by ISO9001, SGS REACH. KPT the provincial powder metallurgy pig iron powder. maintain close collaboration with research institutions universities. institutions.

provide excellent services in terms delivery and shipping. Our pig iron powderare shipped into over 30 countries within North America, South America, Asia, and Europe, have been recognized by customers.We hope work with you to be your trusted reliable supplier.

KPT Company has annual production pig iron powderof 200000 tonnes is equipped with sponge iron atomized powder production lines. KPT is among most technologically advanced, complete largest production facility powder in China.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy