Aya masalah? Mangga hubungi kame pikeun mimitian anjeun!

PertanyaanBubuk liga anu dibuat ku atomisasi vakum mibanda keunggulan bobot spherical pikeun kabubukan, fluiditas anu bagus, distribusi elemen liga anu merata, kandungan oksigen anu rendah, korosi anu bagus tahan, panas tahan, aus tahan, dlsb. anu cocog pikeun cetakan 3D, las semprot, cladding laser sarta bahan proses lianna.

Ciri-ciri

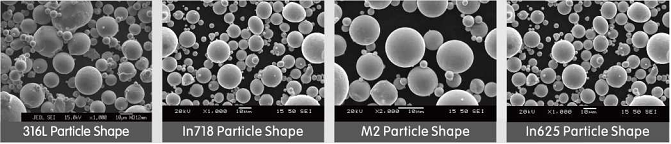

Sphericity nu Gede & Flowability nu Gede.

spesifikasi

| Komposisi kimia bubuk logam | |||||||||

| Produk | Komposisi Kimia(%) | ||||||||

| Alloy | Cr | Ni | Mo | V | Si | Mn | Nb | C | Fe |

| 316L | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤1.0 | ≤2.0 | ≤0.03 | Bal | ||

| 304L | 18.0-20.0 | 8.0-12.0 | <1.0 | ≤2.0 | ≤0.03 | Bal | |||

| 17-4PH | 15.5-17.5 | 3.0-5.0 | Cu:3.0-5.0 | ≤1.0 | ≤1.0 | 0.15-0.45 | ≤0.03 | Bal | |

| 420J1 | 12.0-14.0 | ≤0.6 | ≤1.0 | ≤1.0 | 0.15-0.25 | Bal | |||

| 430 | 16.0-18.0 | ≤0.75 | ≤1.0 | ≤0.12 | Bal | ||||

| H13 | 4.75-5.5 | 1 1-1.5 | 0.8-1.2 | 0.8-1.2 | 0.2-0.5 | 0.32-0.45 | Bal | ||

| M2 | 3.75-4.5 | 4.5-5.5 | 1.75-2.2 | 0.2-0.45 | 0.15-0.4 | W.5.5-6.75 | 0.78-0.88 | Bal | |

| 310S | 24.0-26.0 | 19.0-22.0 | <1.5 | .≤2.0 | 0.2-0.45 | Bal | |||

| S136 | 12.0-14.0 | 0.15-0.4 | 0 8-1.0 | ≤1.0 | 0.2-0.45 | Bal | |||

| CoCrMo | 26.5-30.0 | ≤1.0 | 4.5-7.0 | ≤1.0 | ≤1.0 | Co:Bal | ≤0.35 | ≤1.0 | |

| Sifat fisik serbuk magnit | ||||||

| Produk | Proses | Kasarkeun cair (S\/50g) |

T.D (g/cm³) |

0.C.ppm (ppm gas) |

Spesifikasi (μm) |

Packing (KG) |

| 316L |

Gas atomisasi |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| 17-4PH |

Gas atomisasi |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| M2 |

Gas atomisasi |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| In718 |

Gas atomisasi |

<20 | ≥4.7 | ≤600 | 15-50 | 5/25/50 |

| In625 |

Gas atomisasi |

<20 | ≥4.6 | ≤600 | 15-50 | 5/25/50 |

| AISi12 |

Gas atomisasi |

<20 | ≥5.0 | ≤500 | 15-50 | 5/25/50 |

| AISi10Mg |

Gas atomisasi |

<20 | ≥5.0 | ≤500 | 15-50 | 5/25/50 |

Pamakéan

Hak Cipta © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Kebijakan Privasi