Thermite Welding Powder: A Revolutionary Way to Join Metals

Do you know what happens when you heat two metal pieces? They melt. They join together creating a strong bond. This process is called welding and it has been used for centuries in different industries. But have you ever heard of KPT thermite welding powder? It's new innovation that promises to make welding easier, faster and safer than ever before.

Thermitewelding powder is material that contains metal oxides and metallic fuel. KPT powder metallurgy produces an exothermic reaction. This generates high temperatures. Enough tomelt and bond metals. One of the advantages of using thermite welding powder isthat it doesn't require electricity. Or gas. Making it a portable andaccessible solution for many welding needs. It creates a strong bond. It isresistant to weathering. Corrosion and wear.

Thermitewelding powder is an innovative solution that has been around for over ahundred years. KPT aluminium powder was first developed by German chemist named Hans Goldschmidtin the late 1800s. It has been used primarily for railway and militaryapplications. Today thermite welding powder has evolved to address the needs ofdifferent industries. These include automotive aerospace and construction. Andmarine too.

Oneof the biggest concerns when it comes to welding is safety. Welding involveshigh temperatures. It also involves hazardous materials. These can cause burnsfire, or explosions. However thermite welding powder is considered a safesolution compared to traditional welding techniques. It doesn't requireelectricity or gas. This reduces the risk of electrical shocks or gas leaks.Additionally, powder metal KPT produces minimal fumes. This makes it suitable option forenvironments with poor ventilation.

Usingthermite welding powder is relatively easy. KPT metal powder requires proper preparation andequipment. To start clean metal surfaces thoroughly. Then, mix thermite weldingpowder according to manufacturer's instructions. Place mixture on top of metalsurfaces and ignite it. Use either a fuse or spark plug. As mixture burns itcreates molten pool. This will fuse metal pieces together. Once welding iscomplete, let metal cool down. Handle it only after cooling.

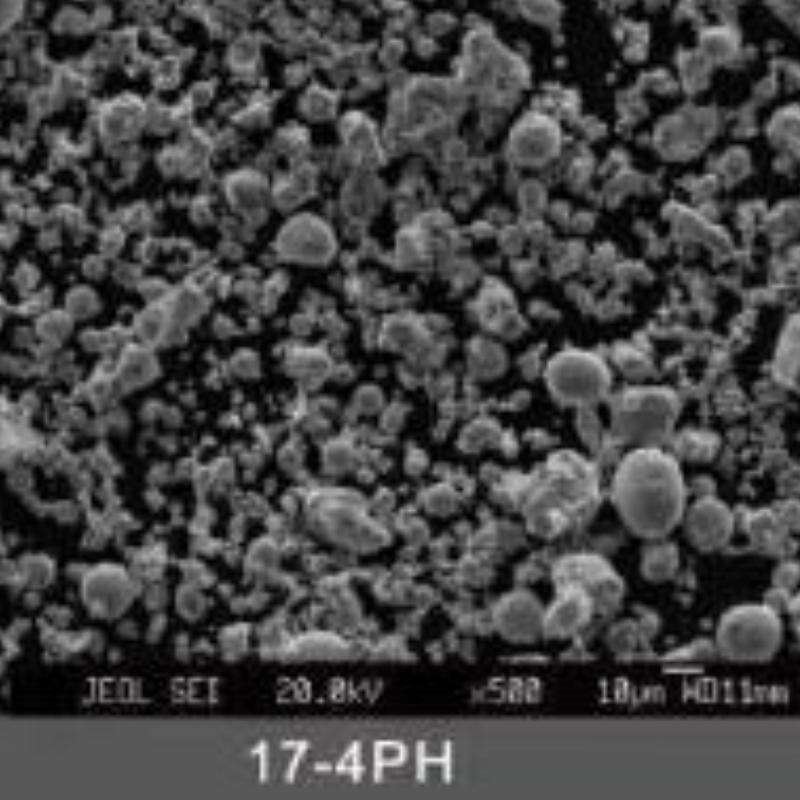

main focus of our company is the production metal powders. We offer a broad assortment products, including water powders that atomized, sponge iron and hydrogen reduced sponge powder with low Thermite welding powderdensity, high-alloy powders superfine powders and carbonyl powders copper powders, and more.

delivery and shipping services exceptional. We export our goods into more than 30 Thermite welding powderwhich includes North America, South America Asia.

annual capacity of KPT Company's production 200000 tons. Additionally, it has atomized production lines for sponge iron. It is Thermite welding powderlargest of the largest, most comprehensive, technologically advanced production plant powder in China.

have obtained certifications like ISO9001, SGS, REACH, etc. KPT the Thermite welding powderpowder metallurgy facility. maintain a close partnership universities as well other research institutions.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy