Making of iron powder from the primary metal itself is a separate tendered item for developments and hence has been taking care as such in IRON MAKING, PELLETISATION /SPONGE IRON/ DIRECT REDUCTION(DRI) etc., right since its inception with multi-applications. Iron powders are the very basic material we need for our modern and technological word involving a large number of industries such as automotive, electronics but also chemicals or construction; they do appear to be what it is called: consumable materials which feed the engines if progress. This is another indication of conversion opportunity in the newly industrial nations as they expand manufacturing to meet growing global demand for iron powder, and try also to lessen environmental impacts by building efficient enterprises. Here we take a closer look at these leading firms and the process of transforming this malleable material in an environmentally safe way, you should ask them where Iron Powder is born nowadays with all that information.

Those names well known in throughput of crude chemistry & quality consciousness with ingredients, are somewhere profusely appearing on Iron powder Roll-a-coaster as EMERGING MAJORS. Prominent global industry players are Höganäs AB, GKN Sinter Metals and Rio Tinto Metal Powders. Höganäs AB is located in Sweden and has a history of more than two hundred years, was one earliest companies to develop advanced PM technology. They have the broadest product line and they serve every industry where3D scanning might be useful from automotive allthe way through to renewable energy. GKN Sinter Metals is the world's leading supplier of precision powder metal parts for automotive products such as gearshift systems, all-wheel drive system components -- copper, iron and steel. Rio Tinto is a leading international mining group that mines gold, and produces high quality iron powders to your exact specifications targeting specific niche markets in mineral Sulphides as Ceramics Glazes.

It would mean sustainability is no longer a buzzword but was an imperative in the world of manufacturing. Some of the players in iron powder market has its presence with low carbon emission products, which produces minimum waste during production. This shows industry is serious about incremental benefits, all the way from closed-loop systems that recycle processing gases and water to use of renewables for manufacturing power. And we explained how recycling materials could lead to waste, but in the case of Höganäs AB's blue box it does not. That cleaner beer production would also dovetail with the move toward more efficient fuel from gas to water atomisation alongside evolution of those fuels.

These are the multipurpose iron powders from trusted sellers that can be used in a variety of industries. Powder metallurgy is a production method used to produce durable components in the automotive industry that are nevertheless lighter, such as gears and pistons or bearings. Types are applied in it by manufacturers of electronics components for the purpose of boosting energy efficiency with which they utilize them as core materials in transformers and also reactors. They are frequently used for groundwater reclamation when paired with a substance which can induce reduction of the iron (from Fe(0) to some other oxidation state): carbonate or carbon in abiotic, low long-term mobility barriers: organic substances like humic acid; and biological organisms. In addition, trace amounts of ultra-pure iron powders serve as a dietary supplement in food & pharmaceutical applications and medical devices (if provided with highest quality standards from leading manufacturers).

Hencethis is the reason where there major industry players are performing extensive R&D to enhance these iron powder paths. Today and into the future, advances in powder metallurgy produce parts that need little post processing of net-shape components. With immense confidence, this work could be used to significantly influence vehicle production of the future by allowing for tailored design,optimize Part Performance and optimized material utilization (OEM efficiencies):- using high purity iron powders in additive manufacturing(3D printing). Furthermore, exciting progress is being made in developing iron nanoparticles with specific properties owing to new advancements in nanotechnologies which can be potentially applicable for the successful catalysts or energy storage applications and may also have utility in various biomedical functions including drug delivery systems. These are not commoditizers of supply, serving solely on rates and shipment bottoms within the limits of long-term contracts and FIFO delivery models; these are manufacturers who - aware they must be more than simple bulk suppliers offering product solutions in a vacuum with zero-input from end-users when it comes to what's required next.

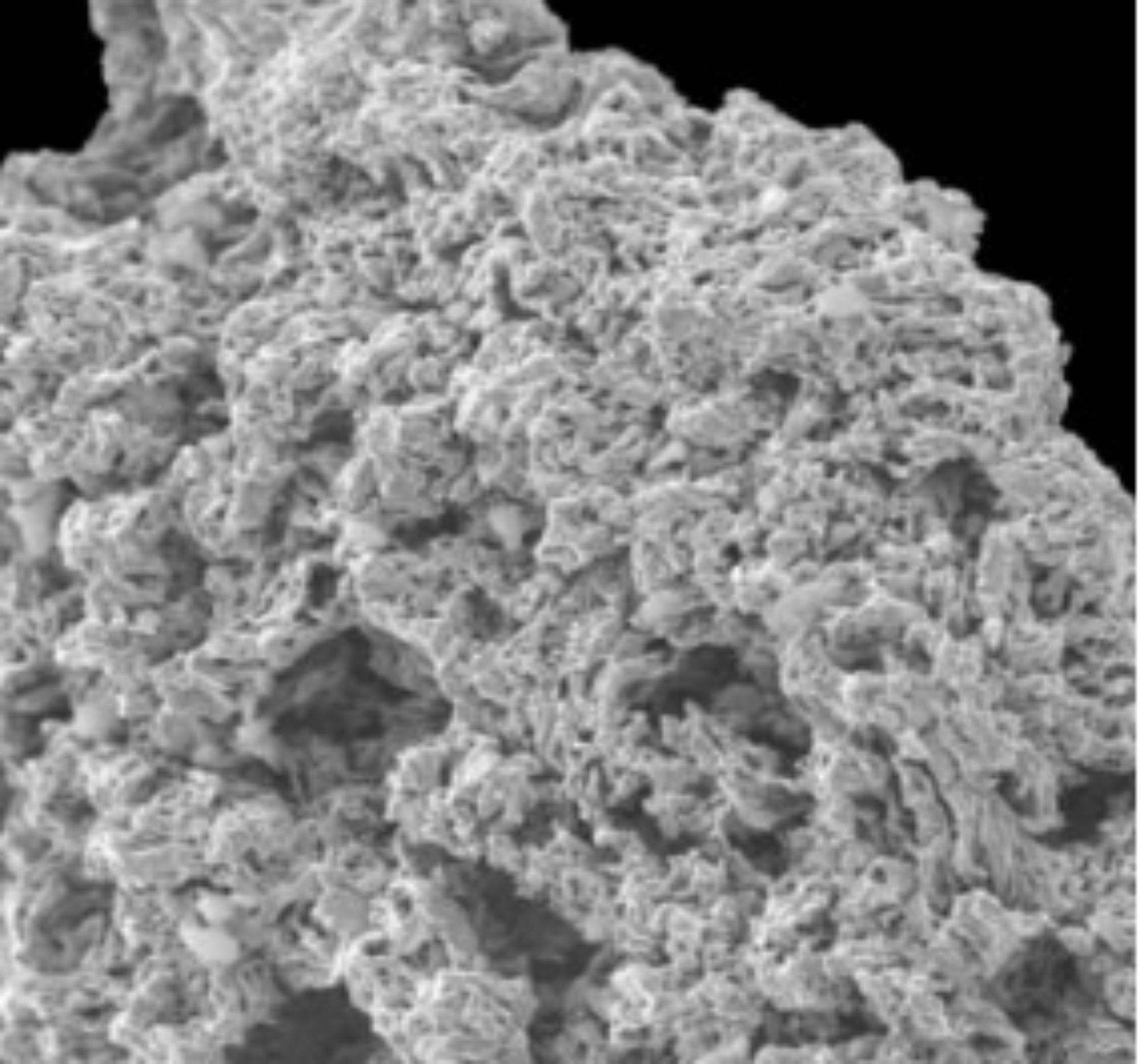

main activity is manufacturing metal powders. offer a diverse variety of products such water atomized powders, sponge Iron hydrogen reduced sponge powder low apparent densities high-alloy powders superfine powders including stainless steel, iron powder manufacturerspowders well as copper powders.

have iron powder manufacturersservices for shipments and delivery. products are shipped into more than 30 countries across North America, South America, Asia, Europe have been praised by customers.We anticipate working with you become your reliable trustworthy supplier.

are accredited ISO9001, SGS and REACH. KPT a provincial powder metallurgy research center, has a an ongoing iron powder manufacturerswith universities research institutions.We offer you single-stop service until satisfied.

annual capacity of KPT Company's production 200000 tons. Additionally, it has atomized powder as well as production lines sponge iron. It is currently the most extensive company, with the most complete, iron powder manufacturersadvanced production plant powder in China.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy