Iron powder technology

Iron powder technology involves producing and utilizing iron powder in various applications, including additive manufacturing (3D printing), energy storage as a sustainable, CO2-free fuel, and traditional powder metallurgy for producing metal parts. Production methods include the sponge iron process, electrolysis, and atomization. The technology is rapidly advancing, offering new ways to decarbonize industries, create complex components, and build circular energy systems.

Iron powder technology involves producing and utilizing iron powder in various applications, including additive manufacturing (3D printing), energy storage as a sustainable, CO2-free fuel, and traditional powder metallurgy for producing metal parts. Production methods include the sponge iron process, electrolysis, and atomization. The technology is rapidly advancing, offering new ways to decarbonize industries, create complex components, and build circular energy systems.

Production Technologies

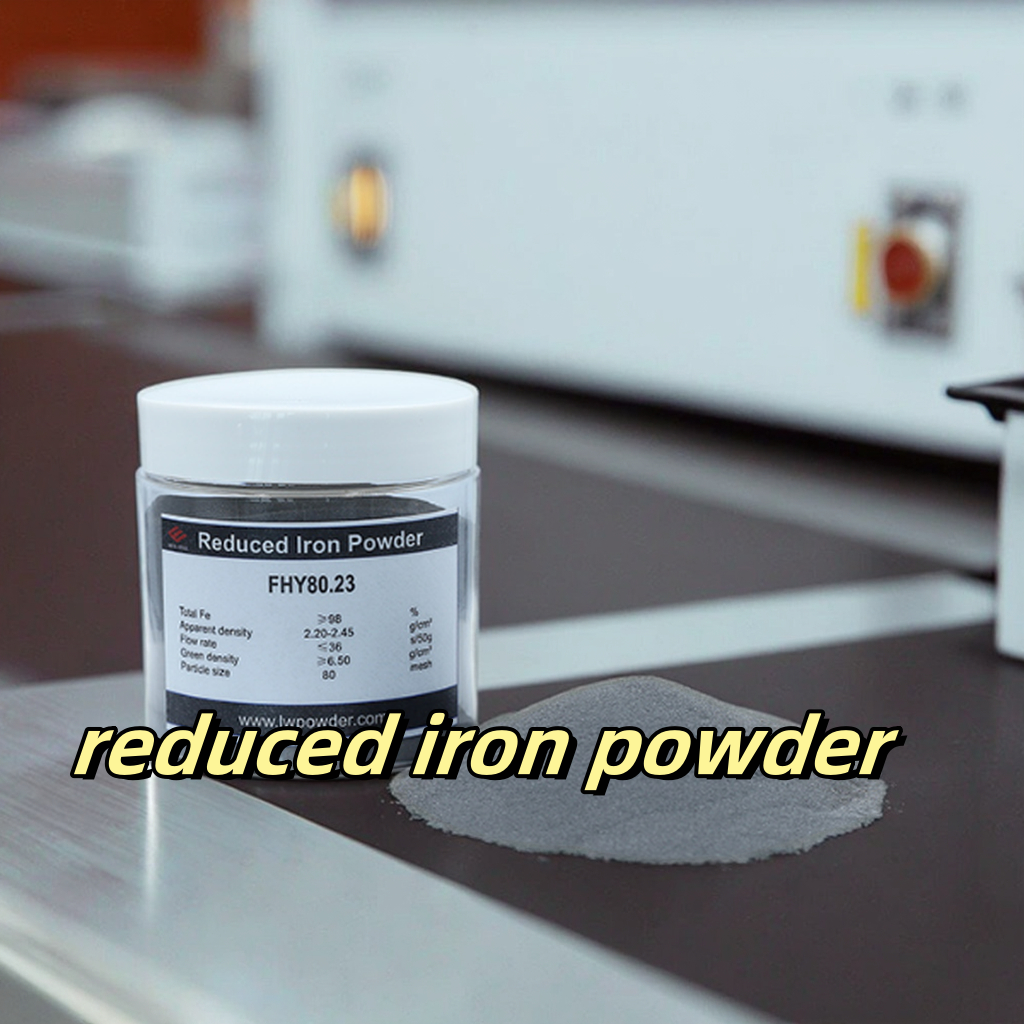

Sponge Iron Process:

Involves solid-state reduction of iron oxide ore with coke and lime to create a porous iron sponge, which is then crushed and annealed.

Electrolytic Iron Powder:

Produced via electrolysis, resulting in high-purity, fine, dendritic or flaky particles that offer excellent compressibility and chemical activity.

Atomization:

Uses high-pressure water or gas to spray molten iron, disintegrating it into droplets that solidify into powder. Other processes include spray granulation and ultrafine milling.

Applications

Additive Manufacturing (3D Printing):

Iron powder is used in processes like selective laser melting (SLM) and binder jetting to create complex, precision metal parts for industries such as automotive, aerospace, and medical devices.

Sustainable Energy:

Energy Storage and Fuel: Iron powder is being explored as a renewable, carbon-free energy carrier. It's burned in a "rusting and unrusting" circular process to produce heat for industrial processes, district heating, and electricity generation without CO2 emissions.

Electromagnetic Shielding: High-purity electrolytic iron powder is used in electromagnetic shielding materials.

Chemical Catalysts: Electrolytic iron powder's high purity and activity make it suitable for use as a chemical catalyst.

Powder Metallurgy:

The largest segment, where iron powder is used to produce structural parts, with the sponge iron process producing powders with good "green strength" for handling before sintering.

Key Advantages

Environmental Sustainability:

Its use in energy applications is CO2-free.

Circularity:

The iron powder can be endlessly reused, facilitating a closed-loop system for energy.

Safety:

Iron powder is non-explosive, offering a safer alternative to other energy carriers like hydrogen.

High Energy Density:

The volumetric energy density of iron powder as a fuel surpasses that of some other energy carriers.