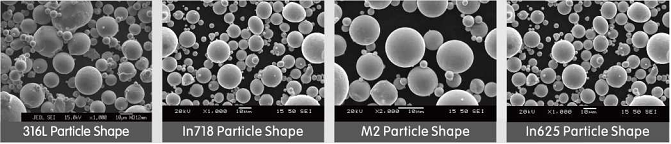

Aljaški prašek proizveden metodom vakuum atomizacije ima prednosti poput potpuno kugastog praška, dobre strujnosti, ravnomjerno raspodijeljenih aljažnih elemenata, niske sadržine kisika, dobre otpornosti na koroziju, toplinsku otpornost, otpornost na šarenje itd., prikladan je za 3D tiskanje, sprjecnu svarenju, laser oblogu i druge procesne materijale.

Karakteristike

Visoka kugastost & visoka strujnost.

specifikacije

|

ALLOY

|

CR

|

Ni

|

Mo

|

V

|

Si

|

Mn

|

NB

|

C

|

- Ne, ne, ne.

|

|

316L

|

16.0-18.0

|

10.0-14.0

|

2.0-3.0

|

|

≤1.0

|

≤2.0

|

|

≤0.03

|

Bal

|

|

304L

|

18.0-20.0

|

8.0-12.0

|

|

|

<1.0

|

≤2.0

|

|

≤0.03

|

Bal

|

|

17-4PH

|

15.5-17.5

|

3.0-5.0

|

Cu:3.0-5.0

|

|

≤1.0

|

≤1.0

|

0.15-0.45

|

≤0.03

|

Bal

|

|

420J1

|

12.0-14.0

|

≤0.6

|

|

|

≤1.0

|

≤1.0

|

|

0.15-0.25

|

Bal

|

|

430

|

16.0-18.0

|

|

|

|

≤0.75

|

≤1.0

|

|

≤0.12

|

Bal

|

|

H13:

|

4.75-5.5

|

|

1 1-1.5

|

0.8-1.2

|

0.8-1.2

|

0.2-0.5

|

|

0.32-0.45

|

Bal

|

|

M2

|

3.75-4.5

|

|

4.5-5.5

|

1.75-2.2

|

0.2-0.45

|

0.15-0.4

|

W.5.5-6.75

|

0.78-0.88

|

Bal

|

|

310S

|

24.0-26.0

|

19.0-22.0

|

|

|

<1.5

|

.≤2.0

|

|

0.2-0.45

|

Bal

|

|

S136

|

12.0-14.0

|

|

|

0.15-0.4

|

0 8-1.0

|

≤1.0

|

|

0.2-0.45

|

Bal

|

|

CoCrMo

|

26.5-30.0

|

≤1.0

|

4.5-7.0

|

|

≤1.0

|

≤1.0

|

Co:Bal

|

≤0.35

|

≤1.0

|

Primjena

Autorska prava © Shanghai Knowhow Powder-Tech Co.,Ltd. Sva prava pridržana - Pravila o privatnosti