The Wizards of Metal Flux Powder

Metal Flux Powder is an incredible substance creating a huge impasto in the world of cost-effective welding. As we get behind the wonders of this product, we reveal how it has most valuable importance for craftsmen and hobbyist alike.

A significant advantage of metal flux powder is the bond strength provided (helping to improve deposit quality), buy helping in removing surface oxides and impurities between metals. This makes successfully welding or brazing to the connecting part much easier. Also, The reduced melting point of flux spreads uniformly over to the metal surface making a well-organized flow and joining action

Metal flux powders are non-corrosive and do not produce a residue or slag as most traditional fluxes. The result is less time wasted cleaning up after welding and there are no concerns over contamination. In addition to this, its compatibility with a variety of metals from thick steel through to fragile brass make it an extremely convenient and must-have piece for metalworkers.

Metal flux powder is a key innovation in the welding and brazing world, which has had some far-reaching impacts. Metal flux powder is "dry", which means that it will activate when exposed to heat without worrying about shelf life, and safety in storage / transport - something you can be explained on typical liquid or paste forms. This KPT magnetic powder individual trait also facilitates the possibility to use it in different temperatures and environments, making them more user friendly.

Metal flux powder is very dangerous work. Always protect yourself from contact of the skin and inhalation by wearing gloves, goggles or a mask when handling dry powder. KPT powder metall is crucial as well, while the work area must be free of open flames or hot surfaces

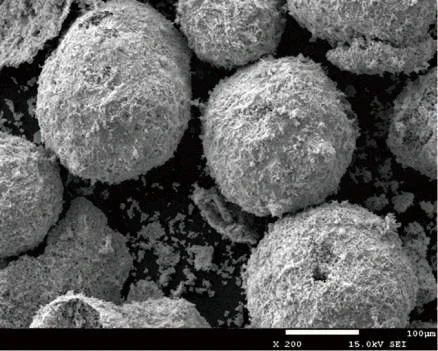

Metal flux powder is straightforward to use and suitable even for novices. After cleaning the metal a little better and adding some extra "molecules" of flux, it acts as that shield making sure solder or filler-metal flows smoothly. A nice feature of agglomerated fluxes that contain KPT copper powders is any residual flux remaining on the metal after it has cooled can be easily cleaned off to reveal a strong, visible weld.

have obtained certifications like ISO9001, SGS, REACH, etc. KPT the Metal flux powderpowder metallurgy facility. maintain a close partnership universities as well other research institutions.

have strong services in terms delivery and shipping. Our products are Metal flux powderinto over 30 countries within North America, South America, Asia, and Europe have been praised by customers.We look forward working with you to be your reliable trustworthy supplier.

KPT Company has annual production capacity 200000 tons and is equipped with sponge iron powder Metal flux powderlines. It is current largest, most extensive technically modern powder production facility China.

primary business is manufacturing metal powders. most popular products include water Metal flux powderiron powder and sponge iron powder. hydrogen reduced sponge iron powder has low apparent density, high alloy powder, superfine iron powder, carbonyl iron powder, copper powders etc.Now our company is providing metal powders used in various industries like powder metallurgy welding, diamond tools, friction materials, specifically brake pads chemicals, surface coatings additive manufacturing , MIM soft magnetic , water treatment soil treatment,

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy