Powder metallurgy is a special method to produce metal parts with the help of small metal powders. These powders are then connected pressed and heated so that they adhere together to form solid pieces. This is very good at producing parts that need to be strong and have the same weight and thickness consistently. At KPT, we like powder metallurgy because it lets us create parts that are not pocked with weak spots or holes. That's super useful in cases when parts need to support heavy loads or work in machines where safety is very important. Unlike other types of metal part making, powder metallurgy puts the power in the hands of the makers so every piece is perfect. That’s less waste, and fewer problems when the parts are actually used in production. Even if the shape is complex or the dimensions change, we can still achieve that correct thickness through over the part. Which is why KPT’s powder metallurgy parts are relied upon by so many industries to do the toughest jobs.

Powder Metallurgy Delivers Consistent Density for Critical Structural Components

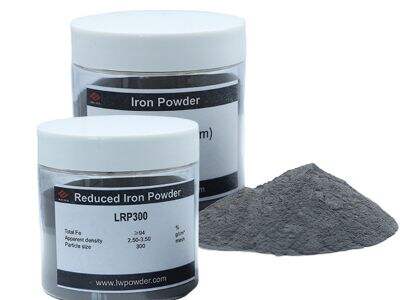

Ensuring that all the parts have equal density is a delicate job. It’s how dense the metal is within the part. Any areas not as dense get weak and may collapse. The powder metallurgy steel is really good at maintaining that density even. We start at KPT prat with top quality metal powders, which are methodically reviewed. Then, we push the powders into molds at regiments pressure. This pushing action forces the powders to be rather close together so there are not a bunch of gaps. After pressing, the parts undergo heating known as sintering. This heat helps further adhere the powders to the skin, without melting them entirely. The result is strong, consistent parts. For instance, a car engine component or structure on heavy machinery manufactured through powder metallurgy will support large loads without cracking. And powder metallurgy enables us to include small amounts of other metals or materials so that parts will be harder or more resistant to rust, among other qualities. You couldn’t do that with molten metal alone. Powder metallurgy also reduces waste by turning wasted powder into a recyclable material. This helps to keep costs low and lessens the motivation for additional metal mining. That even density also translates into parts that wear out more slowly and simply last longer which is pretty critical for the things people depend on in their everyday lives. From bridges to airplanes, powder metallurgy parts from KPT help ensure the safety and strength of structures.

Why It Matters: Powder Metallurgy’s Ability to Reduce Variation in Density for High Performance Parts?

Uniform density is not just about pressing powders hard. Many, many scrupulous steps occur at KPT to ensure that every component is perfect. First, the metal powder metallurgy are very thoroughly mixed to disperse the small grains uniformly. Then, the shape of the mold for forming the part is designed so that it controls pressing of powders to avoid thick and thin points. Occasionally, we use particular machines that press the powder from both sides. This serves to equalize the pressure and prevents one side from becoming denser than the other. The heat step is monitored very carefully after pressing. If the heat is off or on overdrive, in other words too much or too little, the powders won’t adhere properly to your fabric or could shrink unevenly.

Why Powder Metallurgy so Suitable for Structural Component Production?

Powder metallurgy is a special method of making metal objects; it is particularly useful in producing heavy, solid parts which are used in machinery and buildings. Rather than begin with a big block of metal and whittle it down, powder metallurgy begins with minuscule, powdered metals. Those powders are closely pressed together before being heated up to be melded, but not melted, into proper pieces. This process is best for creating structural components, or parts that need to carry weight and remain strong when put under pressure.

One of the reasons powder metallurgy is so effective is that it allows manufacturers to control precisely how metal powders are packed and heated. This control makes parts the same every time, very important if you rely on them in places where safety is at stake. For instance, the parts in cars or airplanes and bridges should not fail for they hold heavy loads. Powder metallurgy facilitates creation of parts with a uniform density that is, the metal is evenly compressed throughout the part. When density is uniform, the part is less apt to contain weak spots that could easily break or wear away.

What You Need to Know as a Buyer: Powder Metallurgy Density Consistency?

Consumers shopping for structural parts created utilizing powder metallurgy should be aware of the significance of density uniformity. Density is a function of how tightly the metal fills space inside a part. More sparser parts can be weaker and more prone to failure. Uniform density refers to the fact that metal particles are distributed uniformly throughout every piece, increasing the part’s strength and making it more predictable in how it will perform at high temp.

When they are building parts for KPT via powder metallurgy, they pay a lot of attention to controlling the item’s density. It begins with a very good grade of metal powders that are regular in size and shape. Then the powders are compressed with just enough pressure to ensure that they fit together snugly. The parts are heated after pressing in a unique furnace that causes the powders to stick together. This is because the process of sintering, which both freezes the part in place and maintains its density.

How Powder Metallurgy Makes Structural Components Perform Better and Last Longer?

Structural components made in powder metallurgy tend to perform better and last long compared to those made in some other procedures. The tiny metal powders are combined and treated to create durable and strong parts. Once the density for a part is consistent, they can handle stress and pressure without cracking or breaking easily. At KPT, our powder metallurgy procedure is aimed at improving both the performance and reliability of the structural parts. Performance means how well a part works, carrying or handling weight, or making it workable with the other parts more comfortably. Reliability means the part keeps working well, even in harsh conditions. Powder metallurgy enhances performance because parts can be made with the exact size and shape. The precision allows the parts to fit better and have little friction hence, wear and tear mainly. Since the metal powders are tightly pressed, the parts are less likely to break because they have few or no tiny holes. The solid parts are better at resisting forces like twisting, bending, or shaking.

Table of Contents

- Powder Metallurgy Delivers Consistent Density for Critical Structural Components

- Why It Matters: Powder Metallurgy’s Ability to Reduce Variation in Density for High Performance Parts?

- Why Powder Metallurgy so Suitable for Structural Component Production?

- What You Need to Know as a Buyer: Powder Metallurgy Density Consistency?

- How Powder Metallurgy Makes Structural Components Perform Better and Last Longer?