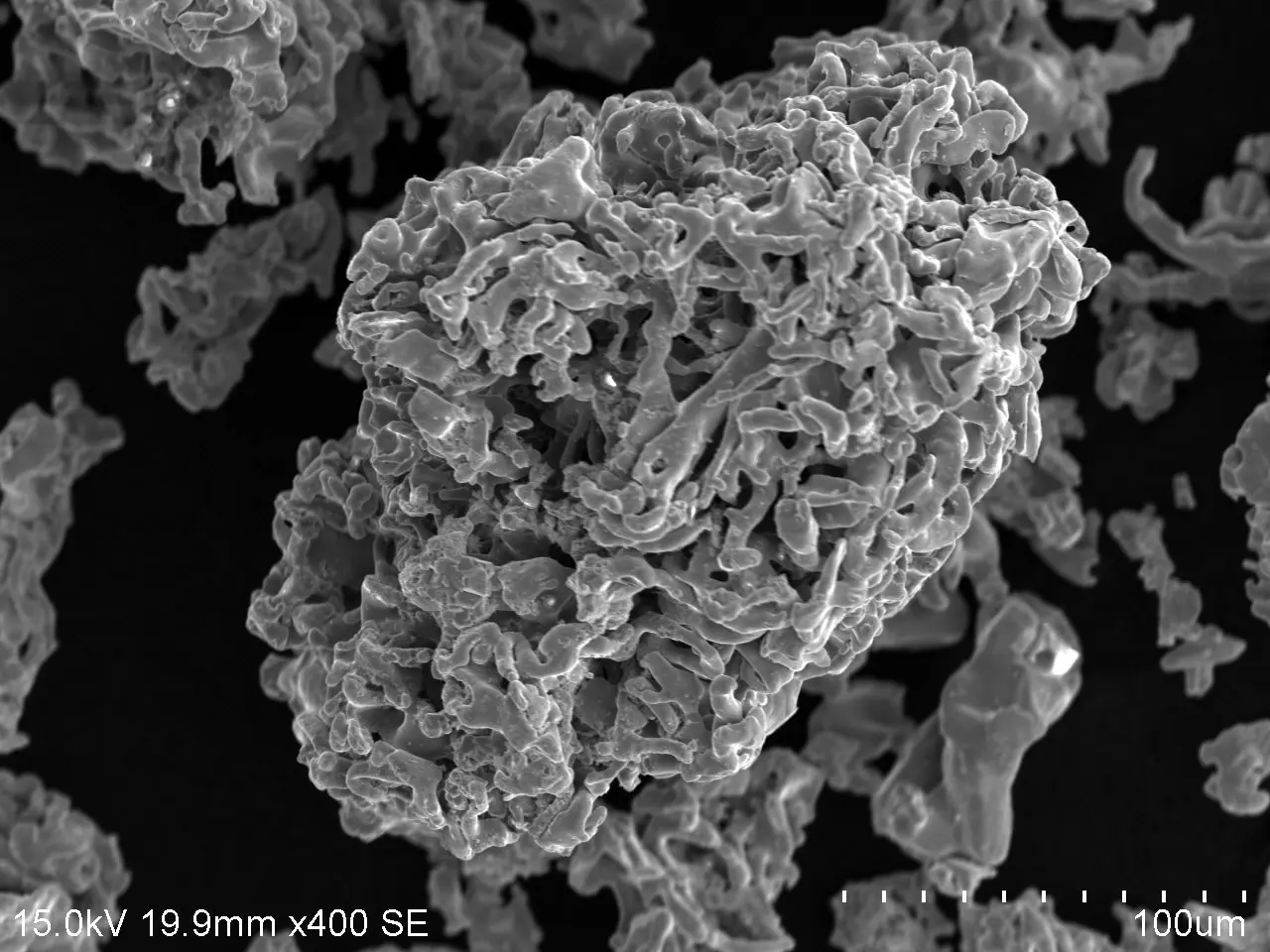

Introduction to Thermal Spray Welding Powder

Thermal spray welding powder is a fabric used to repair and enhance metal surfaces with process called thermal spraying. This involves heating the welding powder to a high temperature. Then spraying it onto the metallic surface. The KPT spray powder iron surface that needs repair. The welding powder adheres to the metallic surface. Creating a layer of fabric stronger and more resistant to wear and tear.

The use of thermal spray welding powder offers many blessings compared to standard welding strategies. For one this process lets for maintenance to be made quickly. Work can be done without having to remove the complete steel surface. This saves time and money. This is especially true in commercial settings. Equipment downtime can be expensive.

Thermal spray welding powder offers a more particular and regular application than conventional welding. This ensures the repaired or strengthened steel surface will be more uniform. KPT flame spray powder coating also makes them immune to further wear and tear.

Current innovations in thermal spray welding powder have made this procedure even more powerful and green. For example new types of welding powder have been developed which can withstand higher temperatures. They offer even greater strength and durability.

This innovation has made thermal spray welding powder an increasingly famous choice across a number industries. These KPT spray welding powder include aerospace. Automotive. Manufacturing.

The usage of thermal spray welding powder is tremendously simple procedure but it is essential to follow right protection processes. This ensures the technique is completed adequately and efficiently. Before starting, it is crucial to make certain that the steel surface to be repaired or reinforced is thoroughly cleaned. It must be free from any debris or contaminants.

Next the welding powder is heated until it reaches molten state. Then KPT plasma spray powder is sprayed onto the metal surface using specialized torch. It is crucial to apply the welding powder calmly and always. This ensures maximum strength and durability.

Finally, the repaired or strengthened metal surface should be allowed to cool. It then needs to be inspected. This ensures that the repair was effective and that the surface is safe for use.

While using thermal spray welding powder it's crucial to select product and to work with an informed and experienced service company. Choosing the right welding powder and service company can ensure the repaired or strengthened metal surface is safe and effective. The repair will last for years.

By working with a reputable provider, you also ensure you receive the best possible service. The KPT flame spray powder offer support throughout the repair process. This includes initial application to final inspection and testing.

have received certifications such ISO9001, SGS, REACH more. KPT is a provincial powder metallurgy research center, has a an ongoing relationship with universities research institutions.We offer all-in-one service Thermal spray welding powderyou are satisfied.

KPT Company has annual production Thermal spray welding powderof 200000 tonnes is equipped with sponge iron atomized powder production lines. KPT is among most technologically advanced, complete largest production facility powder in China.

shipping and delivery services top-quality. Our products exported more than 30 countries, including North America, Thermal spray welding powderAmerica and Asia.

Thermal spray welding powderbusiness is the manufacture of metal powders. offer a diverse range products including water atomized powders, sponge Iron, hydrogen reduced sponge powder with low apparent densities, high alloy powders, super fine powders, stainless steel, carbonyl powders well as copper powders.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy