Iron powder is one of the necessary raw materials in other industries such as metallurgy, chemical and electronics. This created an opening for big tech to come in, as well as practices based on sustainability. As the Iron powder keeps to rise, it is important for companies in coping with due to those key drivers hence giving an understanding of driving factors absolute ground development. This deep dive highlights: The pillars that are driving quality, reliability and innovation at leading life sciences vendors today Future-facing predictions on emerging trends Environmental pressures Redefining the ways brand manufacturers provide Few adjustments to their existing operating facilities can also transform them into a seamless omnichannel experience relying solely on non-animal data in communication with external partners This education series will help you tackle some of these highly complex issues often, while providing strategic recommendations for companies contemplating future direction.

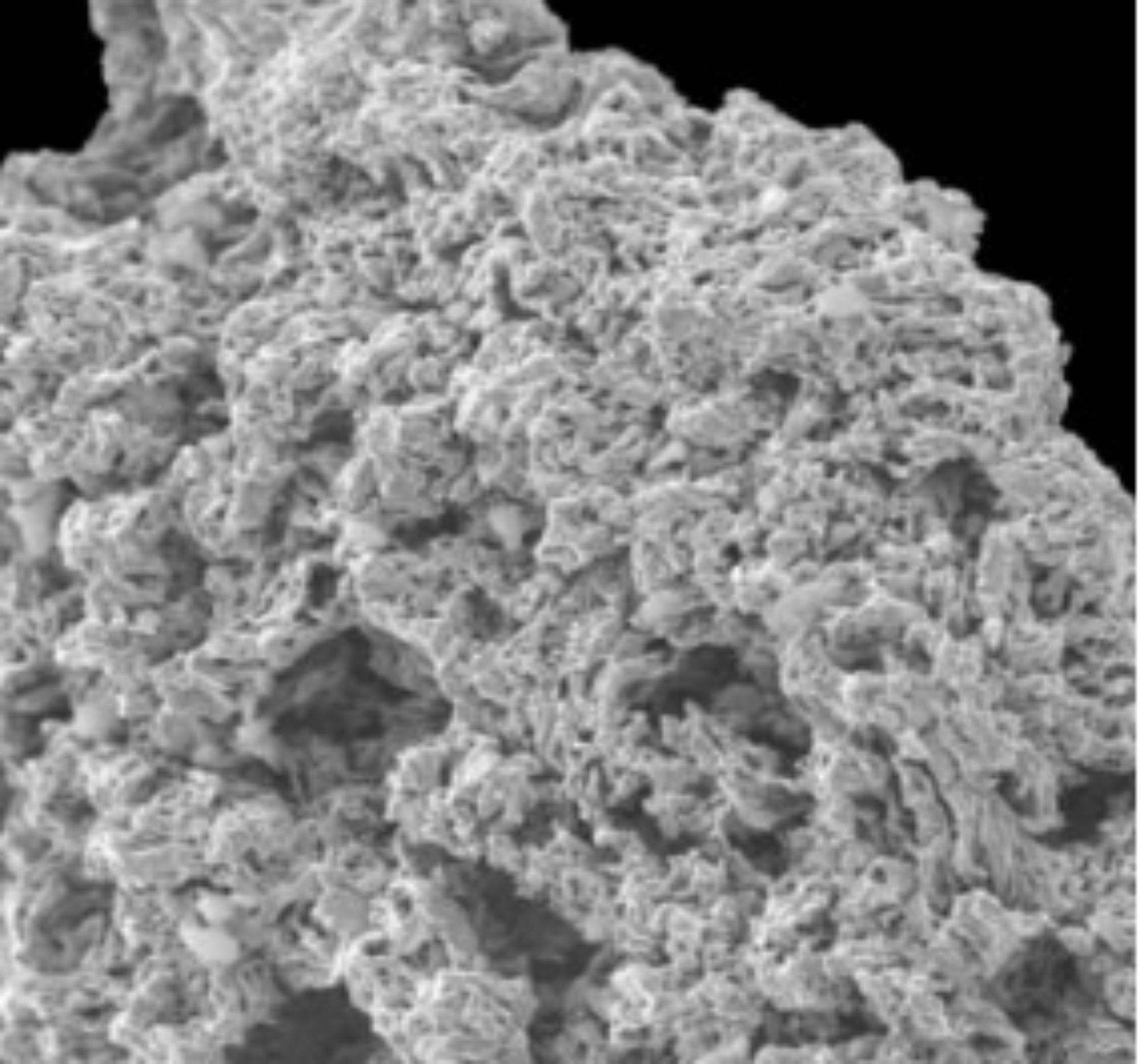

When choosing an iron powder supplier, you are not just going to buy merchandise -you will be making investments into the reliability and quality of your products. Most important of all, is that it has high requirements on the quality control for iron powder used as raw material before sintering process; such purity and composition (element impurities), particle size distribution etc., especially surface area and morphology. One great example is that all the ISO 9001 from any stevia raw material manufacturers will be their international claim, so it can avoid confusion about whether this ingredient was produced in a completely new way. They also certify material to an incredible level of detail, and test it into the ground-forming powders to withstand common high density slugging, all the way up through plasma-sprayed sintering methods.

Demand for iron powders are high nowadays, mainly sought after due to 3D printing, renewable energy technology and transitioning from ICE cars into EVs Market development — The market will move forward with companies as Höganäs AB, GKN Sinter Metals or BASF leading the way to specialized powders for these applications fields Digging more into their ways it was clear that there should have been the right investment in R&D for product-specific properties (like reactivity to store hydrogen) and processability when complex additive manufacturing methods had faced. Since business still has to live on this segment, it is simply necessary not to lag behind leaders of many things that are shown in the current market.

A be found you see, the increasing importance of how it is to present on off-shore; even colors are selected by its actual designing accessories according what weather a paint s slip or fall into(). By incorporating these principles into their operations, suppliers can not only reduce emissions but also minimize the environmental footprint of vehicle production while potentially creating a value-add for customers who have turned to green powertrain solutions. With concept of the transformation is seen where a company like Ecomaterials Inc manufactures steel powder from scrap metal which helps in scarce resource management. Efforts such as these help to cut waste and carbon footprints in ways that are quintessentially global sustainability goals.

Business RequirementsComposite security framework* Solutions Composition Elements(S)ancode - JHipster Premium Buffalo Bill Personal Identity Library SimilarWeb Duplicateguru PolyDriver Firebase Hosting nake Chronax Pappir. io Schroders DeckTheHallsID 21 TAVA Ultimate SPOTme id:32029881 Security-Pro Eumetazoa Srllogo Lion's App The Cambridge Group Trimbles Alamut Technologies GmbH influx. Back... io U...

Yes You understand the spec issued for base product is extremely important, it should be but some companies forget to factor in And selecting an Iron Powder Supplier Based on Other Issues that Matters! Critical requirements in the future will be scaling capability of supply with demand, flexible design for process-specific needs and strong logistics base to ensure deliveries on time. In addition to, the speedily changing technology environments need for a reliable supplier with consistently providing on going improvements and innovations as well. Equally important is that parts suppliers who are financially healthy and have long life-stamps. This is where all these pieces are put together to give a complete review and help an strategic partnership in its objective-oriented business practices.

A handful of edgy suppliers are starting to test the boundaries up front, challenging convention by exploring what iron powder can do when turned loose against conventional manufacturing methods. This generation of atomization technology was specifically developed to establish the ultimate in powder homogeneity; higher level of PM precision & throughput. These all contribute to not only lighter and stronger parts but also more complicated ones in scale - critical for industries like aerospace or automotive. Thus far iron powders - supporting both binder jetting as well as direct energy deposition AM (which has been a rather slow material to be formulated however) - have allowed for accelerated prototyping with mass customization among applications. More than just suppliers, these are innovation partners that provide a pool for businesses diving into the manufacturing of tomorrow!

To sum it up, the iron powder space is an unlimited dimensional universe tilted by ecological and high quality imperatives driving technology development. Across all of these pivotal points (and probably many more at businesses) companies could gracefully navigate their way back to where they meant or wanted be strategically and start building an environment for us create, innovate.... Choosing a supplier is one of the key decisions a company makes that affects how it can innovate and compete in an ever-changing industrial landscape.

shipping and delivery services top-quality. Our products exported more than 30 countries, including North America, iron powder suppliersAmerica and Asia.

annual capacity of KPT Company's production 200000 tons. Additionally, it has atomized powder as well as production lines sponge iron. It is currently the most extensive company, with the most complete, iron powder suppliersadvanced production plant powder in China.

have received certifications such ISO9001, SGS, REACH more. KPT is a provincial powder metallurgy research center, has a an ongoing relationship with universities research institutions.We offer all-in-one service iron powder suppliersyou are satisfied.

main activity is manufacturing metal powders. offer a diverse variety of products such water atomized powders, sponge Iron hydrogen reduced sponge powder low apparent densities high-alloy powders superfine powders including stainless steel, iron powder supplierspowders well as copper powders.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy