Iron powder is a powerful component used in several different industries. The highest purity version is Iron Powder 98, Unsurprisingly, given its name this patent includes a high 98% pure metallic content. It is a key material that plays influence significant roles within modern metallurgy, manufacturing and chemical processes as well as in advanced technologies. The following write-up below will describe the numerous ways and benefits to using iron powder 98 in various industries.

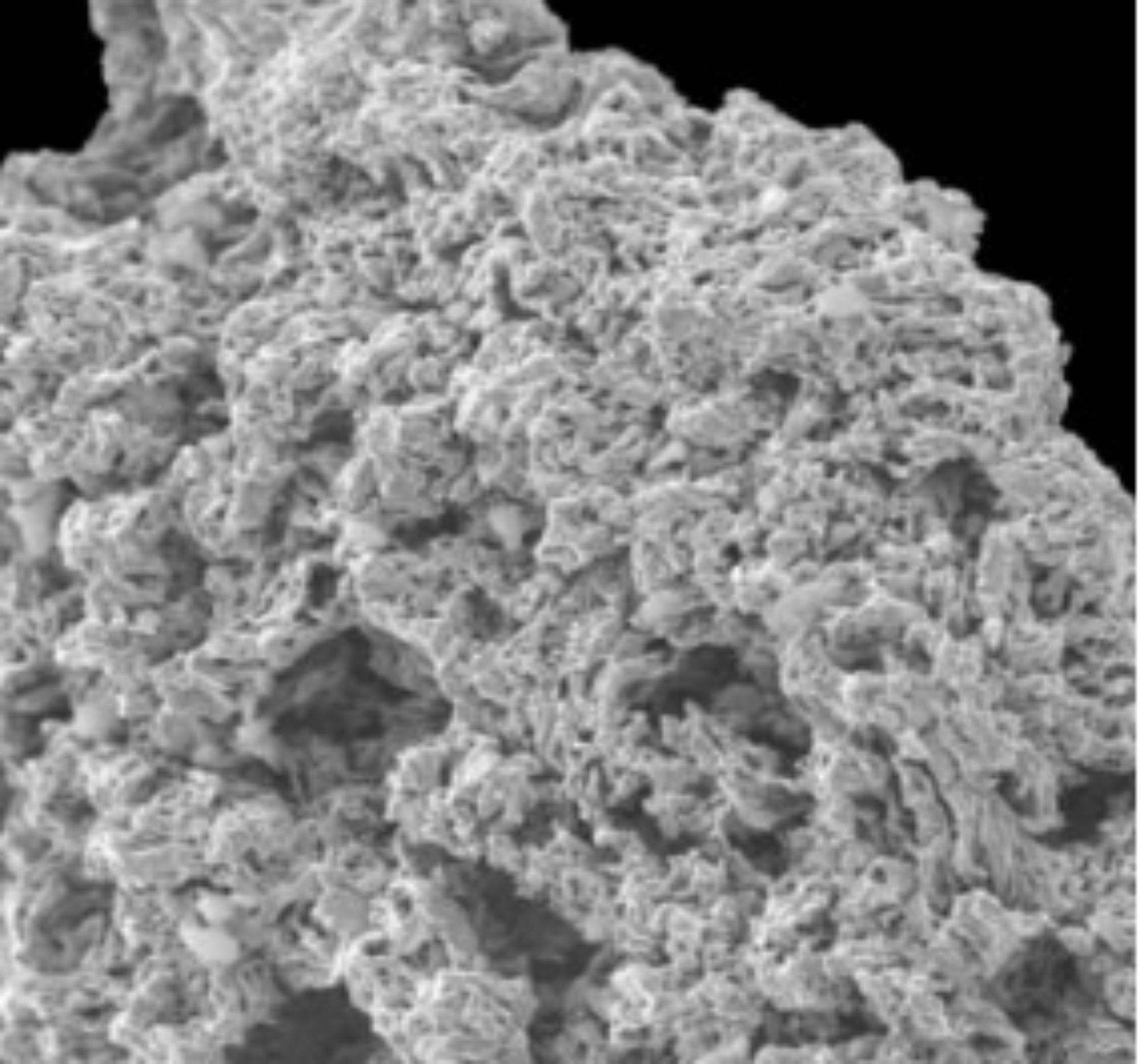

High standard quality Iron powder 98 is known as a very flexible material and finds its application in applications which require precision & consistency. These characteristics, combined to excellent chemical and physical properties high reactivity, narrow particle size distribution in-situ formation (no agglomeration), impurity-free etc., have facilitated the unique uses of these materials as well those for industrial or scientific harsh environments. This type of powders are suited to applications such as the powder metallurgy industry producing complex high mechanical strength components which in turn benefit end-products used in numerous alternative industries.

The metallurgical industry highly needs iron powder 98 as it is crucial to improve the quality and productivity of manufacturing processes. This high purity minimizes contamination when alloying and produces finished goods with the highest strength:weight ratio, corrosion factors. Iron powder 98 is also relevant in manufacturing, such as the molding of powders (powder injection Molding - PIM), which allow shapes rather complex to be manufactured with the least amount of machining and more effectively at a lower cost. In addition to performing standard powder metallurgical processes, this special grade of ONYX offers manufacturers the essential ingredient for higher performance specialty materials such as soft magnetic composites used in electric motors and transformers making electronics more efficient.

Iron powder 98 not only plays a vital part in metallurgy but also has revolutionized the chemical industry. As it will easily be reduced for example from producing titanium dioxide manufacturing, and recovering metals form their oxides. Iron powder 98 has a considerable application potential in environmental remediation with the main advantage of being able to separate pollutants from water treatment as it uses an iron-based reduction-precipitation process. Furthermore, this power also worked constructively for the generation of hydrogen by water splitting essential to clean energy infrastructure.

With a very promising energy solution that leads the iron powder 98 to be seen as one of technology with great advancements in power storage systems next generation like Iron-Based batteries, such as iron-air or flow is possible due its low-cost environmentally friendly and large amounts present on earth. These are critical for balancing grids that depend on intermittent solar and wind further. Unlike lithium-ion batteries, the iron-and-salt systems not have a virtually no fire risk and energy footprint during their manufacture and disposal are several orders of magnitude smaller than tradition Western material procurement.

offer solid service for delivery and shipments. products are exported into more than 30 countries within North iron powder 98, South America, Asia, Europe and have been praised by customers.We anticipate working with you become your trusted reliable supplier.

main business includes manufacturing metal powders. most popular products include water atomized iron powder as well sponge iron powder. hydrogen reduced sponge iron powder, low apparent density, high alloy powder, super fine iron powder stainless steel powder, carbonyl iron powder, copper powders etc.Now our company providing metal powders used in different industries, including powder metallurgy iron powder 98tools, welding , friction materials, specifically brake pads chemicals, surface coatings, additive manufacturing ,MIM soft magnetic, water treatment soil treatment, etc.

are accredited by ISO9001, SGS and REACH. KPT powder iron powder 98centre for province. maintain close collaboration with universities other research institutions.

annual capacity of KPT Company's production 200000 tons. Additionally, it has atomized powder as well as production lines sponge iron. It is currently the most extensive company, with the most complete, iron powder 98advanced production plant powder in China.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy