Everything You Need to Know About Friction Powder: The Different Applicability And the Prospective Technologies this Approach Provide For Humanity

Friction powder is a material that few people know about, but it is indispensable for many everyday consumer products. In the form of brake pads we use for or cars or a casing around bullets, this versatile material is used extensively to generate traction and ensure smooth motion. We soon made it all the way to friction powder in a world bursting with its boundless uses.

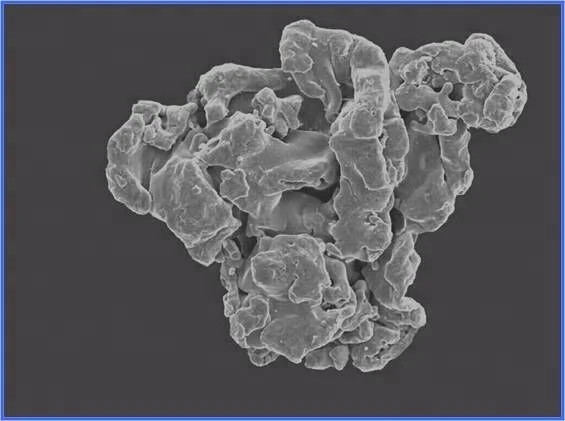

A Look Inside the Friction Powder

The actual friction powder traditionally contains an amalgamation of ultra-fine particles from: graphite, copper, bronze and yes even diamond. This powder (with the binding agent and particles ) is mixed such that they are inter linked. Like when you sprinkle Friction Powder between two surfaces that are moving against one another, and then it slows the lock or blocks both of them in place completely.

Uses Fill inside Gas permeability (%) Automotive brake pads Friction granule, powder High When the brake pedal is pressed, these will push against ttheires initiating some friction which in turn decrease speed of vehicle. At the same time, friction powder helps keep up-grain grip of pads to tires after they have been cycled several times.

Friction powder is which we find in fire ammunition. The bullet travels at a high rate of speed as it exits the muzzle. Frictional powder is to prevent the bullet from falling out past its casing and in order that it properly fires down barrel.

In addition, Friction powder is widely used in the manufacture of mechanical parts such as bearings and gears. It is used in the applications where friction powder can be controlled to prevent wear and tear of parts, so that life span increases resulting low maintenance requirement.

As beneficial as friction powder is, it has been an environmental problem. Among these examples is that of the worn powderthing over time, like brake pads being worried into dust particles in air. These particles can cause adverse health effects to human, and the environmental risk is revealed according to its material nature. Note that recycling and waste concerns are also produced when the brake pads require replacing.

This is being evolved other friction powders as an interim solution and will be more sustainable. All that development into powers and additives (and what you can already buy) is focussed on good old Zirconia, which will change with use to of course - but its still money well spent taking care...) - that in the end, as I read on twitter this morning will make the industry veer toward educating themselves more about recycling.

Selection of the friction powder for a specific application is associated with various problems. Decisions are based on amount of friction desired, as what is used in the powder and cost advices. These factors are what manufacturers need to consider when executing in order to reach peak performance with the least environmental impact.

New uses of friction powder are emerging as technology continues to improve. Another new development is the use of friction powder in self-lubricants. Offering extra launch aid as it releases the friction dust only partially, thereby reducing the intended effect from such gear and stopping breakage before when expected. If it works as intended the innovation could alter how stuff is made and enhance their sturdiness, convenience.

Development of Green Friction Powders With more and more consumers wanting to buy eco-friendly products, manufacturers seek new materials for the production of friction powder or at least in environmentally friendlier ways.

So in the end, even though you almost have never heard of friction powder before this story is that makes the performance and safety products offer. Friction powder is what prevents the brake pads, or bullet casings as well from breaking down and allows products to work properly; so that you can use them however you please. With the continuous growth of technology and demand for current/eco-friendly products, we can expect to see more novel friction powder substances providing new avenues to improved product performance and sustainability.

main activity is manufacturing metal powders. offer a diverse variety of products such water atomized powders, sponge Iron hydrogen reduced sponge powder low apparent densities high-alloy powders superfine powders including stainless steel, friction powderpowders well as copper powders.

provide excellent services in terms delivery and shipping. Our friction powderare shipped into over 30 countries within North America, South America, Asia, and Europe, have been recognized by customers.We hope work with you to be your trusted reliable supplier.

have been certified such as ISO9001, SGS, friction powdermore. KPT is a provincial powder metallurgy research center, has a the close collaboration with universities research institutions.provide you with single-stop service until satisfied.

KPT Company has annual production capacity of 200000 tonnes also has sponge iron and the production atomized powder. It is currently the most extensive, most comprehensive most technologically advanced production plant friction powderin China.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy