Advantages of Using Direct Reduced Iron Powder in Steel Making. DRI (Direct Reduced Iron) powder is the major raw material which used in making steel. Iron ore is a naturally existing resource and it undergoes special process to obtain in usable form. In 2020, to manufacture direct reduced iron one could employ a variety of iron ore grades in co-operation with coke coal or natural gas. Such a blend of features goes along way into making an important material for the steel industry.

Its impurity reduction capacity is the key aspect which avoids air pollution, hence it uses less environment-friendly in comparison to conventional methods. This KPT reduced iron powder and carbonyl iron powder is significant because of the general public good thing about cleaner air. Furthermore, DRI powder can assist with the exact cuts of steel in a like manner how chainsaw functions successfully. Steel made from DRI powder emits around 75% less carbon dioxide (CO2) then if produced using coal power, it is well known fact that CO2 can get trapped in the atmosphere leading to changes in out climate system. Traditional methods, which often require pig iron and scrap metal that can be high in CO2 emissions.

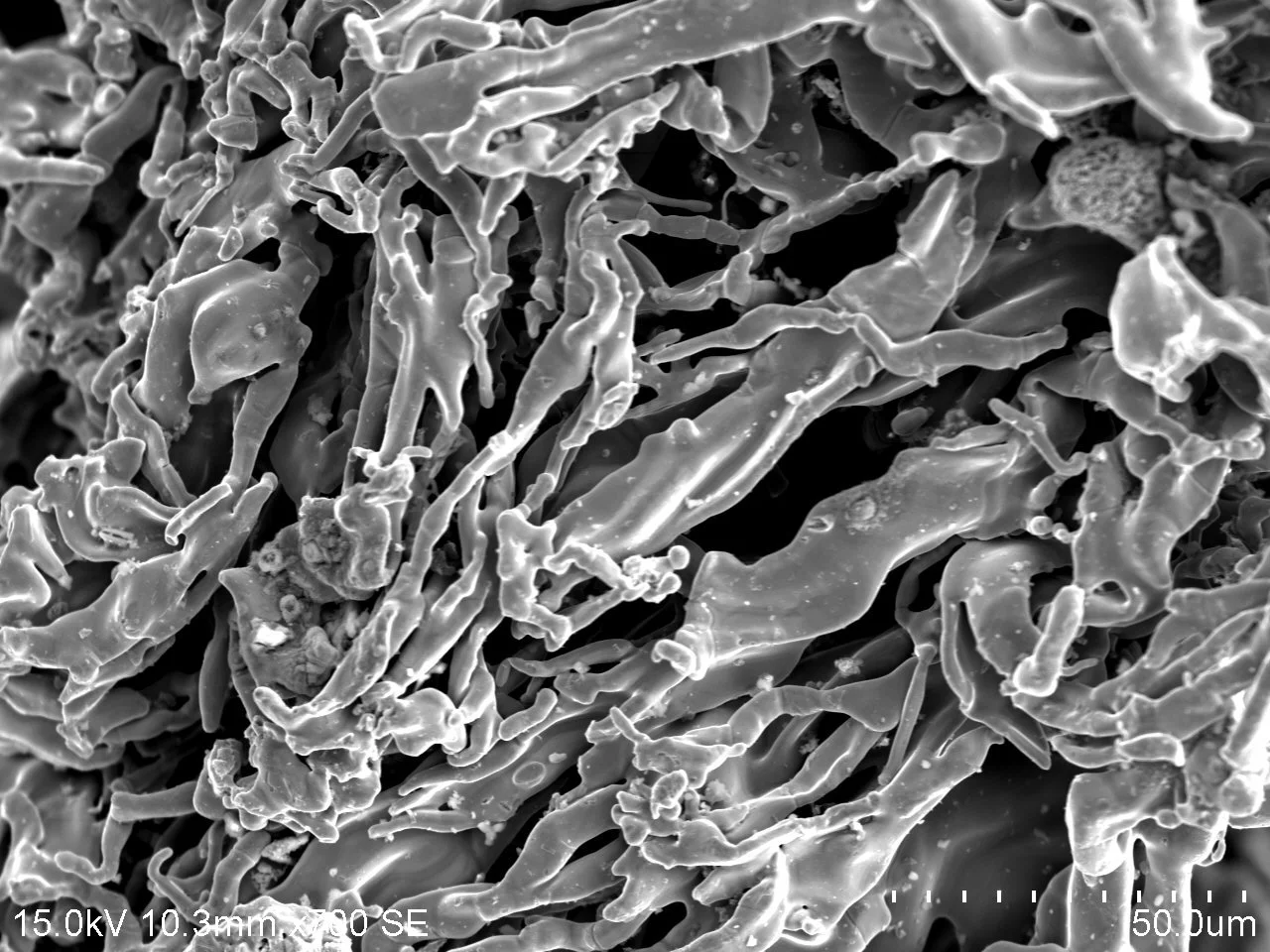

It is created using a proprietary mix of chemicals which results in DRI powder being an excellent choice for businesses that are involved in steel fabrication processes. The minds behind these companies have the capacity to produce different types of steel with structure flexibility, this makes them versatile in using various steels under applications like building cars and other structures. During production, the KPT hydrogen reduced iron powder and wrought iron powder coating is contained so that it does not commingle with other materials. This way it keeps the quality of it is steel at a high level, making suitable for use as raw material to produce solid and resistant products that comply industry standards.

Demand for DRI powder as well as iron powder has shifted significantly in recent years. Lots of companies are scrambling to find greener ways to make steel. The answer not only satisfies this demand but at the same time provides an alternative route to a key raw material on all future steel plants known as hot metal. That shift is critical since businesses are working to minimize their carbon footprint. An increasing number of factories already employ DRI, direct reduced iron since it is a way to produce steel with lower energy costs. This energy efficiency KPT electrolytic iron powder allows companies to produce steel more efficiently, which may translate to cost savings. Using DRI powder in their operations could also reduce the steel industry's carbon footprint, or amount of greenhouse gases produced. This benefit is tremendous for our planet. These processes, unlike in ancient times when there were high-energy methods of production and causing pollution caravanserai that DRI something is often used energy-efficient cleaner fuels such as natural gas or coal environment with low emissions.

There is always research going on which primarily focuses towards the improvisation of methods used for producing DRI powder. Work is underway on next generation of hydrogen-enriched technology in production. This transition is exceptionally important because it would be a cleaner and less expensive means of producing steel. Hydrogen is an attractive option that can further lower carbon emissions and add to the sustainability of steel production.

Conclusion: KPT reduced iron powder 400 mesh is favored for steel making. It has many benefits. This iron powder is environmentally safe because it helps to reduce pollution, enables the manufacturing of high-quality steel that meets industry requirements and with time has limited applications in the Steel Manufacturing sector as well. With the industry continuing to grow and evolve, there is little doubt that DRI powder plays a crucial role in fulfilling the dream of sustainable steel production.

provide excellent services terms of delivery and shipping. products are shipped to more than 30 countries across North America, South America, Asia, Europe and have been praised by customers.We look forward working with you to Direct reduced iron powderyour reliable trustworthy supplier.

primary business is manufacturing metal powders. most popular products include water Direct reduced iron powderiron powder and sponge iron powder. hydrogen reduced sponge iron powder has low apparent density, high alloy powder, superfine iron powder, carbonyl iron powder, copper powders etc.Now our company is providing metal powders used in various industries like powder metallurgy welding, diamond tools, friction materials, specifically brake pads chemicals, surface coatings additive manufacturing , MIM soft magnetic , water treatment soil treatment,

annual capacity of KPT Direct reduced iron powderproduction is 200000 tonnes, it has atomized powder sponge iron production lines. KPT is among most advanced in technology, the most comprehensive and largest production facility powder in China.

have obtained certifications like ISO9001, SGS, REACH, etc. KPT the Direct reduced iron powderpowder metallurgy facility. maintain a close partnership universities as well other research institutions.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy