ISO: The Alternative of Countless Applications - Blended Steel Powder

The high speed of our modern world creates challenges everywhere, which leads to an increased demand for robust and reliable products in all sectors; these are the types of more durable versions of alloys we need going forward. Difference in service life of products may enlighten the fact to those who are looking for not just performance enhancement but with that durability as well, which we can largely achieve using fine and pure alloy steel powder. Today in this blog, we will talk about various Advantages, Developments along with precautions and Prospective Applications of Alloy Steel powder.

Advantages

Actually powder of alloy steel posses a whole lot more advantages over the normal steels These powders are resistant to corrosion as well, and any sort of harsh environmental conditions similarly do not have an effect on them. The make use of steels are the alloy that we can process by Special Metals, it is never possible to label them in pure metals but exist with much more high melting points when compared normal stainless steels., Those long-life forged adopt specific metallics from Japan such as inconel 625. They are very resistant to abrasion and that is why it makes sense as an industrial material, shaving costs.

Innovation

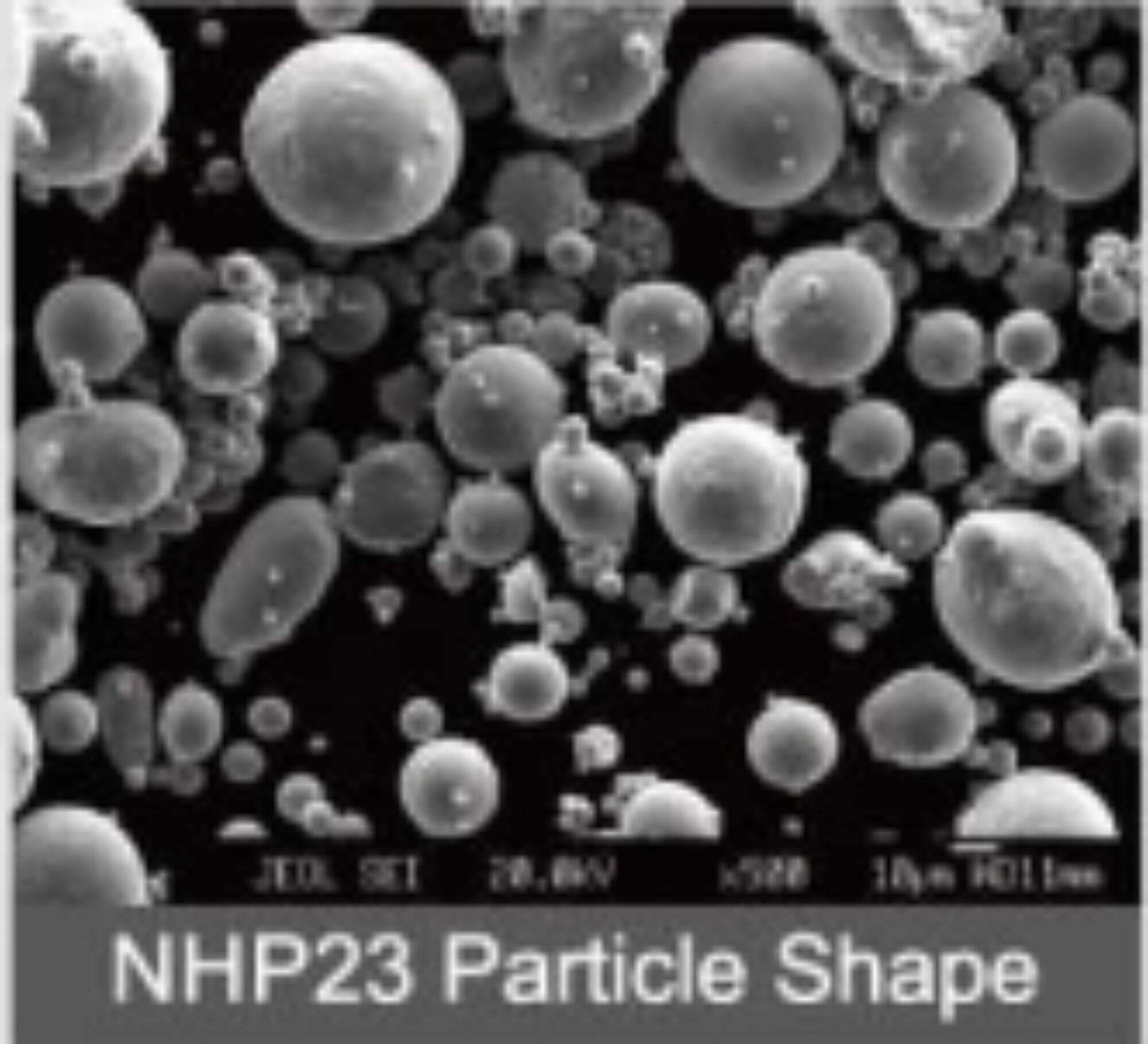

Alloy steel powders have been around for a while, and there has since been further development in the making of it. It the development of altogether new manufacturing processes e.g. Gas Atomisation invention, led to a leap in technology and eventual production improvements which deliver high performance alloy steel powders with reduced dimensions variance etc.. Gas atomization is used to shape similar size and shape of powder particles, which makes them flow more freely and avoids defects in the end product.

When it comes to metal powders like alloy steel powder, explosions and fires are two typical hazards that come with using them. But proper safety equipment can take the danger out of it. The powders must be mixed in such a way they can dry out, and handled only when dry or stable; storage is similarly require very careful set of precautions. For these reasons the powder has to be handled while wearing appropriate personal protection equipment. If people follow to abide by those safety measures about 40% could be avoided on the course.

In contrast alloy steel powders are utilized in automotive industries, engineering and medical industry as well as jewellery. These are mainly applied in manufacturing some high performance parts such as gears, bearings and springs. That makes them even better suited to challenging environments - where conventional materials can fall short. In addition, alloy steel powders are a key ingredient in the manufacturing of welding rods - used to join stainless steels with other metal.

How to Use

The versatile characteristics of alloy steel powders make them suitable in multiple applications. In a process known as metal feeds for 3D printing, metallic powders may be combined with binders and lubricants to form slurries. More over these powders can also serve as feed in powder metallurgy where they are moulded with suitable molds and then sintering them. The powder is then sintered at high temperatures and the melted particles solidify to create a metal part.

Quality and service play a critical role in alloy steel powders. The most important aspect is selecting a supplier who ca supply powders at the right quality and more importantly grade that you require. It would assist the supplier in knowing its application, powder properties and production process completely. Consumers also need a good post-purchase experience with tech support, and problem resolution so that they have no issues on their way.

The quality attribute of alloy steel powders, decides their effective use and service life. Different elements make up the quality of powder, Investment in materials (example purity), method related or it may be affected with inspection. If you want to take your powders up a notch, it mostly boils down to relying on an expert hand with high standards for quality.

KPT Company has annual production capacity of 200000 tonnes has Alloy steel powderiron and powder atomization lines. The company the most technologically advanced, complete largest powder production enterprise China.

are accredited by ISO9001, SGS REACH. KPT is the provincial powder Alloy steel powderfacility. We maintain close partnership other research institutions.

company's main business is producing metal powders. offer broad range of products including water atomized powders, sponge Iron, hydrogen reduced sponge powder low apparent density, high alloy powders, Alloy steel powderfine powders stainless steel, carbonyl powders copper powders, more.

provide excellent services in terms delivery and shipping. Our Alloy steel powderare shipped into over 30 countries within North America, South America, Asia, and Europe, have been recognized by customers.We hope work with you to be your trusted reliable supplier.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy