Is daar 'n probleem? Kontak ons asseblief om u te bedien!

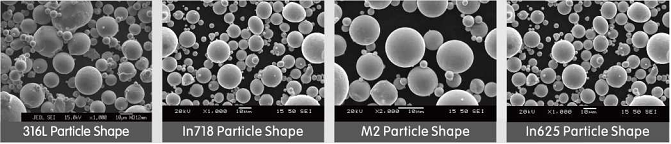

OndersoekDie legering poeder gemaak deur vakuum-atomisering het die voordele van volkome sferiese poeder, goeie vloeibaarheid, ewe verspreiding van legeringselemente, lae sykeinhoud, goeie korrosieweerstand, hittebestendigheid, slijtstofweerstand, ens. Dit is geskik vir 3D-druk, spuitwels, laserbedekking en ander prosesmateriaal.

Eienskappe

Hoë Sferisiteit & Hoë Vloeibaarheid.

spesifikasies

| Chemiese samestelling van metaalpoeier | |||||||||

| Produkte | Chemiese samestelling(%) | ||||||||

| Legering | Kr | Ek | Mo | V | Ja | Mn | Nb | C | Fe |

| 316L | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤1.0 | ≤2.0 | ≤0.03 | Bal | ||

| 304L | 18.0-20.0 | 8.0-12.0 | <1.0 | ≤2.0 | ≤0.03 | Bal | |||

| 17-4PH | 15.5-17.5 | 3.0-5.0 | Cu:3.0-5.0 | ≤1.0 | ≤1.0 | 0.15-0.45 | ≤0.03 | Bal | |

| 420J1 | 12.0-14.0 | ≤0.6 | ≤1.0 | ≤1.0 | 0.15-0.25 | Bal | |||

| 430 | 16.0-18.0 | ≤0.75 | ≤1.0 | ≤0.12 | Bal | ||||

| H13 | 4.75-5.5 | 1 1-1.5 | 0.8-1.2 | 0.8-1.2 | 0.2-0.5 | 0.32-0.45 | Bal | ||

| M2 | 3.75-4.5 | 4.5-5.5 | 1.75-2.2 | 0.2-0.45 | 0.15-0.4 | W.5.5-6.75 | 0.78-0.88 | Bal | |

| 310S | 24.0-26.0 | 19.0-22.0 | <1.5 | .≤2.0 | 0.2-0.45 | Bal | |||

| S136 | 12.0-14.0 | 0.15-0.4 | 0 8-1.0 | ≤1.0 | 0.2-0.45 | Bal | |||

| CoCrMo | 26.5-30.0 | ≤1.0 | 4.5-7.0 | ≤1.0 | ≤1.0 | Co:Bal | ≤0.35 | ≤1.0 | |

| Fisiese eienskappe van magneetpoeder | ||||||

| Produkte | Proses | Liquideiteit (S\/50g) |

T.D (g/cm³) |

0.C.ppm (ppm gas) |

Spesifikasies (μm) |

Verpakking (kg) |

| 316L |

Gas atomisering |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| 17-4PH |

Gas atomisering |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| M2 |

Gas atomisering |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| In718 |

Gas atomisering |

<20 | ≥4.7 | ≤600 | 15-50 | 5/25/50 |

| In625 |

Gas atomisering |

<20 | ≥4.6 | ≤600 | 15-50 | 5/25/50 |

| AISi12 |

Gas atomisering |

<20 | ≥5.0 | ≤500 | 15-50 | 5/25/50 |

| AISi10Mg |

Gas atomisering |

<20 | ≥5.0 | ≤500 | 15-50 | 5/25/50 |

Toepassing

Kopiereg © Shanghai Knowhow Powder-Tech Co.,Ltd. Alle regte voorbehou - Privaatheidsbeleid